Steel injection packers provide superior sealing and pressure capabilities. They are ideal for high-pressure crack injection applications. These tools outperform traditional methods like plastic packers and surface ports. This analysis will demonstrate why a Steel Injection Packer consistently proves more effective than its conventional counterparts. It highlights their robust design and enhanced performance in demanding environments.

Key Takeaways

- Steel injection packers are strong tools. They fix concrete cracks. They work well under high pressure.

- Traditional methods use plastic packers or surface ports. They are simpler and cost less. They work for small jobs.

- Steel packers handle high pressure better. They seal cracks tightly. This prevents leaks and blow-outs.

- Traditional methods have limits. They cannot handle high pressure. They may not seal as well.

- Steel packers are good for big jobs. They fix important structures. They last a long time.

- Traditional methods are good for small cracks. They work for DIY projects. They fit small budgets.

- Choosing the right tool is important. It depends on the crack. It depends on the project needs.

Understanding Crack Injection: The Basics

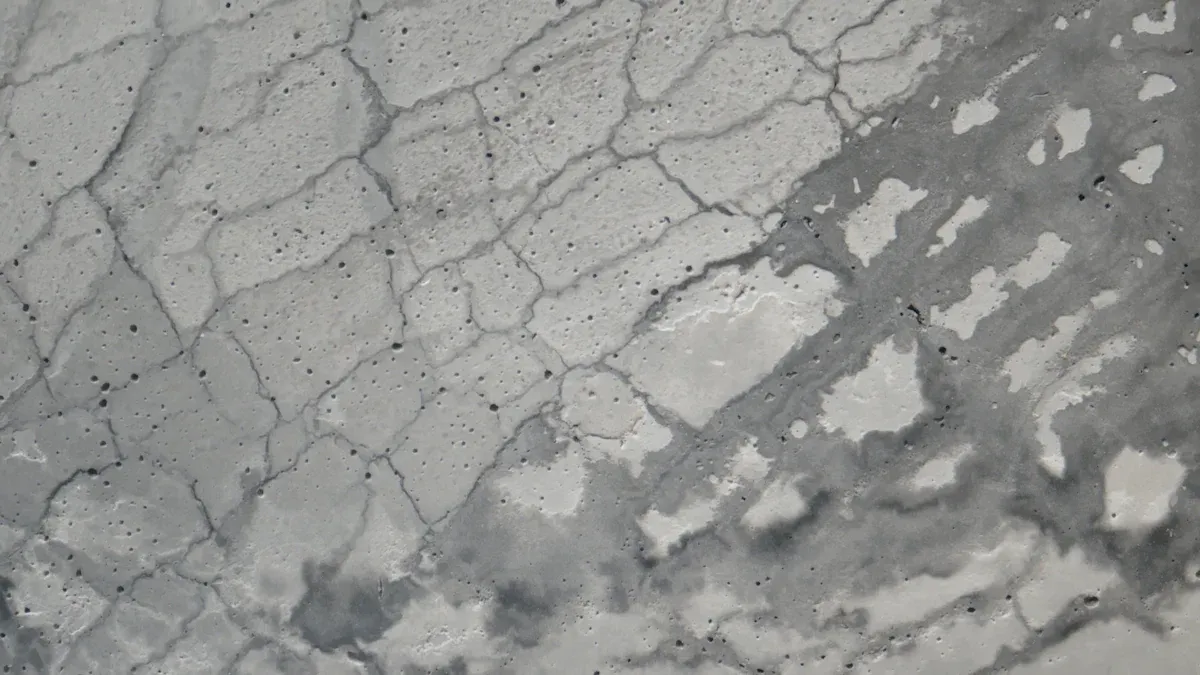

Crack injection represents a critical technique in maintaining and restoring concrete structures. This process involves introducing specialized materials into cracks to address various structural and environmental issues. Understanding its fundamental purposes and the tools involved is essential for effective application.

Purpose of Crack Injection

Crack injection serves multiple vital functions in construction and infrastructure maintenance. Each purpose contributes to the longevity and safety of concrete elements.

Structural Repair and Reinforcement

The primary function of crack injection involves restoring the structural integrity of concrete. It aims to return the concrete to its pre-cracked condition. This process also prevents the repaired structure from cracking again. Epoxy crack injection specifically restores structural and infrastructural features weakened by cracks. It uses a rigid, high-strength epoxy resin to permanently bond both sides of a crack, effectively restoring the concrete’s original integrity. This method offers the most effective and permanent solution for reinforcing foundations or walls requiring concrete crack repair.

Waterproofing and Leak Sealing

Crack injection also plays a crucial role in waterproofing and sealing leaks. Many structural cracks often accompany leaks. Epoxy injection helps stop these leaks. Polyurethane injection, a flexible and water-reactive solution, specifically seals cracks actively leaking or exposed to moisture. This prevents water ingress and protects the internal components of the structure.

Preventing Material Deterioration

By sealing cracks and reinforcing structural elements, crack injection prevents further material deterioration. It stops moisture, chemicals, and other harmful agents from penetrating the concrete. This protection extends the service life of the structure and reduces the need for more extensive, costly repairs in the future.

The Role of Injection Packers

Injection packers are indispensable tools in the crack injection process. They perform several key functions that ensure the successful delivery of repair materials.

Creating a Sealed Injection Point

Packers establish a secure and sealed entry point into the crack. Installers insert the packer into a pre-drilled hole, ensuring a tight fit. This seal prevents the injected material from escaping prematurely or leaking onto the surface. A secure seal is paramount for directing the material precisely where it needs to go.

Facilitating Material Delivery

Packers facilitate the controlled delivery of liquid polymers, such as polyurethane or epoxy, into the cracks. This process requires a gradual introduction of material, often at low pressures ranging from 20 to 50 psi. Low-pressure injection allows applicators to monitor the process carefully, ensuring a complete fill. Incomplete injection often leads to repair failure. Higher pressures, exceeding 50 PSI, can prove ineffective as liquids tend to follow the path of least resistance, potentially traveling up the crack without fully filling it to the soil side.

Maintaining Injection Pressure

Packers help maintain the necessary injection pressure throughout the repair. This sustained pressure ensures the material penetrates deep into the crack, reaching all voids and fissures. Larger diameter packers, for instance, permit higher injection pressures and generally prevent blow-out more effectively, ensuring a secure seal and thorough material distribution. This capability is vital for achieving a comprehensive and lasting repair.

Steel Injection Packers: Engineered for Demanding Applications

Steel injection packers represent a significant advancement in crack repair technology. Engineers design these tools for the most challenging and critical applications. Their superior construction and performance set them apart from traditional methods.

Design and Material Superiority

The design of steel injection packers prioritizes strength and reliability. This focus ensures they perform effectively under extreme conditions.

Robust Mechanical Construction

Steel injection packers feature a robust mechanical construction. This design allows them to withstand significant forces during installation and injection. Their sturdy build minimizes the risk of failure, even in demanding environments. This reliability contributes to a higher construction quality and pass rate for repair projects.

High-Strength Steel Alloys

Manufacturers construct these packers from high-strength steel alloys. These materials provide exceptional durability and resistance to corrosion. The use of premium alloys ensures the packers maintain their integrity when exposed to various chemicals and harsh conditions. This material choice makes them ideal for long-term use.

Specialized Sealing Mechanisms

Steel packers incorporate specialized sealing mechanisms. These mechanisms create a tight, secure seal within the drill hole. The effective seal prevents backflow of injection material and ensures precise delivery into the crack. This precision is crucial for achieving a complete and lasting repair.

Key Advantages of Steel Injection Packers

Steel injection packers offer several distinct advantages over other methods. These benefits make them the preferred choice for professional applications.

Exceptional Pressure Resistance

Steel injection packers demonstrate exceptional pressure resistance. They withstand high injection pressures without leaking or moving from their drill hole. Packers Plus Titanium™ XV completion solutions, which include steel components, are engineered for differential pressures up to 18,000 psi (103 MPa). These solutions have 15,000 psi (103 MPa) ratings on all metal parts. This capability ensures the grout actually enters the target cracks and defects, enhancing the long-term effect of reinforcement and waterproofing.

Superior Sealing Capability

These packers provide superior sealing capability. Their design ensures a tight fit, preventing material loss and ensuring efficient delivery. This reliable seal contributes to a good waterproof effect and stable quality under pressure.

Enhanced Durability and Longevity

Steel packers offer enhanced durability and longevity. Their robust construction and high-quality materials allow for repeated use. This extended lifespan makes them a cost-effective solution for contractors.

Potential for Reusability

Many steel injection packers are reusable. Professionals can clean and inspect them after each use. This reusability reduces waste and lowers overall project costs for large-scale operations.

Ideal Applications for Steel Injection Packers

Steel injection packers excel in specific, demanding applications where performance is paramount.

Critical Structural Concrete Repairs

Steel packers are particularly beneficial for critical structural concrete repairs. They offer significant strength and good resistance to oxidizing components found in acrylate/acrylic gels. This makes them suitable for demanding crack injection scenarios where high injection pressures are necessary and reliability is paramount. They withstand extreme construction conditions, making them ideal for repairs requiring durability and adaptability to high-pressure environments.

High-Pressure Epoxy and Urethane Injections

These packers are essential for high-pressure epoxy and urethane injections. They handle the forces required to push viscous materials deep into fine cracks. This ensures thorough penetration and effective bonding.

Active Water Leaks and Challenging Environments

Steel injection packers perform well in active water leaks and challenging environments. Their robust design maintains integrity even when facing constant moisture or aggressive chemicals. This ensures effective sealing and waterproofing.

Grouting Voids and Cavities

Professionals use steel packers for grouting voids and cavities. They facilitate high-pressure grouting of internal voids, honeycombs, and cavities in concrete components. This process injects epoxy, PU, and polyurethane to improve overall strength and durability.

Crack Treatment on Special Substrates

Steel packers are suitable for crack repair on stone, tiles, and rock. They minimize drilling damage. Their relatively thin rubber sealing section enables reliable expansion sealing in small boreholes and narrow cracks, avoiding secondary damage.

Traditional Crack Injection Methods: Simplicity and Specificity

Traditional crack injection methods offer straightforward solutions for various repair scenarios. These techniques prioritize ease of use and cost-effectiveness, making them suitable for specific applications. They provide viable alternatives when projects do not demand the high-pressure capabilities of steel packers.

Plastic Injection Packers

Plastic injection packers represent a common traditional method for crack repair. They provide a simple, effective means to introduce repair materials into concrete cracks.

Basic Design and Materials

Plastic packers typically feature a simple design. Manufacturers produce them from durable plastics like polypropylene or nylon. A common design includes a barrel, a rubber sealing element, and a zerk fitting or button head for material attachment. This construction allows for a basic seal within a drilled hole.

Disposable Nature

These packers are generally disposable. Contractors use them once and then discard them after the injection process. This disposable nature eliminates the need for cleaning and maintenance, streamlining project workflows. It also reduces labor costs associated with packer recovery and preparation for reuse.

Ease of Installation

Installers find plastic packers easy to install. They simply insert the packer into a pre-drilled hole and tighten it, often by hand or with a basic wrench. This straightforward installation process contributes to faster setup times on job sites. It also requires minimal specialized training for technicians.

Surface Ports

Surface ports offer another traditional approach to crack injection, particularly for surface-level repairs. They provide a non-invasive method for sealing cracks.

Low-Pressure Application

Technicians primarily use surface ports for low-pressure injection applications. They are ideal for introducing thin, low-viscosity materials into cracks. This method ensures the material flows gently into the crack without excessive force.

Surface-Level Crack Sealing

Surface ports excel at sealing cracks visible on the concrete surface. Workers adhere these ports directly over the crack, creating a small reservoir. This setup allows the injection material to penetrate the crack from the surface downward.

Minimal Drilling Requirements

Surface ports require minimal or no drilling. This characteristic makes them a preferred choice when preserving the concrete’s integrity is crucial. It also reduces labor and equipment needs, simplifying the repair process.

Advantages of Traditional Methods

Traditional crack injection methods offer distinct benefits, making them appropriate for certain types of projects. Their simplicity and economic advantages often drive their selection.

Cost-Effectiveness for Specific Jobs

Traditional methods provide a cost-effective solution for many repair tasks. The lower material cost of plastic packers and surface ports reduces overall project expenses. This makes them an attractive option for budget-conscious projects or less critical repairs.

Simplicity for DIY and Small Projects

These methods are highly suitable for do-it-yourself (DIY) enthusiasts and small-scale projects. Their straightforward application process does not require extensive training or specialized equipment. Homeowners and small contractors can easily implement these solutions.

Quick Setup for Non-Critical Repairs

Traditional methods allow for quick setup and deployment. Their ease of installation and minimal preparation requirements enable rapid response to non-critical repairs. This efficiency helps complete projects faster, minimizing disruption.

Inherent Limitations of Traditional Methods

Traditional crack injection methods, while offering simplicity, present several inherent limitations. These drawbacks often restrict their effectiveness in more demanding repair scenarios. Understanding these constraints helps professionals select the most appropriate injection technique for each project.

Lower Pressure Tolerance and Blow-Out Risk

Traditional methods, such as plastic packers and surface ports, exhibit a significantly lower pressure tolerance. Plastic packers, made from less rigid materials, often deform or fail under high injection pressures. This can lead to a "blow-out," where the packer expels from the drill hole. Surface ports, relying on surface adhesion, also cannot withstand substantial pressure. This limitation restricts their use to low-pressure applications. It also increases the risk of material leakage or incomplete crack filling when higher pressures are necessary.

Less Effective Sealing

The sealing mechanisms of traditional methods are generally less effective. Plastic packers rely on a simple expansion or friction fit within the drill hole. This often creates a less robust seal compared to more advanced designs. Surface ports depend on the adhesive bond to the concrete surface. This bond can weaken or fail under pressure or if the surface is not perfectly prepared. Consequently, these methods are more prone to backflow of injection material. They also allow material to escape around the injection point, leading to inefficient delivery and potential waste.

Limited to Specific Crack Types and Sizes

Traditional methods possess inherent limitations regarding the types and sizes of cracks they can effectively address. Plastic packers perform best in relatively uniform, medium-sized cracks. They struggle with very fine hairline cracks, where material penetration becomes difficult. They also prove less effective in wide or irregular cracks, where achieving a consistent seal is challenging. Surface ports are primarily suitable for shallow, surface-level cracks. They cannot effectively deliver material deep into the concrete structure. This restricts their application to non-structural or cosmetic repairs.

Reduced Durability of the Injection Point

The injection points created by traditional methods often exhibit reduced durability. Plastic packers, being disposable, are not designed for long-term integrity within the concrete. They can degrade over time, especially when exposed to certain chemicals or environmental factors. Surface ports, once the injection is complete, typically get removed or remain as a surface attachment. Neither method contributes to the long-term structural integrity of the injection point itself. This can compromise the overall longevity of the repair, particularly in areas subject to ongoing stress or environmental exposure.

Direct Comparison: Pressure Handling and Injection Effectiveness

The ability to manage and sustain injection pressure fundamentally differentiates crack repair methods. This capability directly impacts the effectiveness and longevity of the repair. Steel injection packers and traditional methods exhibit significant differences in this critical area.

Sustained High-Pressure Delivery

Effective crack injection often requires consistent pressure to ensure the repair material reaches every part of a crack. The choice of packer significantly influences this delivery.

Capability of Steel Injection Packers

Steel injection packers excel in high-pressure applications. They are specifically engineered to withstand and maintain substantial injection forces. For instance, laboratory tests confirm steel packers can sustain pressures exceeding 400 bar. This robust performance allows for deep penetration of viscous materials into fine and complex crack networks. The main components of these packers, often made from 42 CrMo steel, ensure high strength and durability. They maintain their shape and function even under extreme pressure. Their excellent sealing performance actually improves as pressure increases. This makes them ideal for repeated high-pressure cycles.

| Material | Typical Safe Pressure Range |

|---|---|

| Steel | 3500 psi to 5800 psi (or above 400 bar in lab tests) |

| Plastic | Around 250 bar or below 60 BAR |

Limitations of Traditional Methods

Traditional methods, such as plastic packers and surface ports, face severe limitations regarding high-pressure delivery. Plastic packers are suitable for low-pressure tasks, typically operating safely at around 250 bar or less. Some plastic packers are even limited to below 60 BAR. They lack the inherent strength of steel. This makes them unsuitable for high-pressure work. They can also fail if technicians use them incorrectly. Surface ports, relying on surface adhesion, cannot withstand significant pressure. This restricts their use to low-pressure applications. These limitations often prevent the complete filling of cracks, especially those that are deep or intricate.

Risk of Premature Failure

The risk of premature failure during injection poses a significant concern for any crack repair project. This risk varies greatly between steel and traditional methods.

Blow-Out Resistance

Steel injection packers offer superior blow-out resistance. Their robust mechanical construction and high-strength steel alloys ensure they remain securely in place even under extreme pressure. This prevents the packer from expelling from the drill hole. This reliability contributes to a higher construction quality and pass rate for repair projects. In contrast, traditional plastic packers are prone to blow-outs when technicians apply excessive pressure. This can lead to material waste and necessitate re-drilling or re-sealing, increasing project time and cost.

Material Integrity Under Pressure

Maintaining material integrity under pressure is crucial for a successful repair. Steel packers ensure the injection material flows into the crack without compromising the surrounding concrete or the injection point itself. However, traditional methods carry a higher risk of compromising material integrity. Injecting at too high a pressure, often with manual tools lacking proper control, can lead to incomplete crack injection. This is a common reason for crack repair failure. Excessive flow and pressure can also create micro-cracks in the concrete and around the injection port. This causes the liquid to escape rather than infiltrating the crack effectively.

Uniform Material Distribution

Achieving uniform material distribution throughout the crack is the ultimate goal of any injection process. This ensures a complete and lasting repair.

Achieving Deep Crack Filling

Steel Injection Packer technology facilitates deep crack filling. Their ability to sustain high pressure allows the repair material to penetrate the entire depth and length of the crack. This includes even the finest capillaries. This ensures the material reaches all voids and fissures, creating a comprehensive bond. This capability is vital for structural reinforcement and effective waterproofing.

Preventing Incomplete Fills

Traditional methods often struggle to prevent incomplete fills. Their lower pressure tolerance and susceptibility to blow-outs mean the material may not reach the deepest or most remote parts of a crack. Inadequate surface preparation, inappropriate sealant selection, or incorrect application technique can also contribute to incomplete fills. These issues include insufficient depth or working beyond recommended times. This leaves sections of the crack untreated. Such incomplete fills compromise the repair’s effectiveness and can lead to future deterioration or leakage.

Direct Comparison: Sealing Integrity and Repair Longevity

The effectiveness of a crack repair hinges on its sealing integrity and how long that seal lasts. These factors directly influence the repair’s success and the structure’s long-term stability. Steel injection packers and traditional methods show clear differences in these crucial areas.

Preventing Backflow and Material Loss

Preventing backflow of injection material is essential for efficient and complete crack filling. It ensures the material reaches its intended destination without waste.

Superior Sealing of Steel Injection Packers

Steel injection packers offer superior sealing capabilities. Their robust design creates a tight, reliable seal within the drill hole. This seal effectively prevents the injected material from flowing back out. NRV injection packers, often made of stainless steel, incorporate a one-way valve mechanism. This valve allows injection material to flow into the concrete. Crucially, the one-way valve prevents backflow or leakage of the injected material. This mechanism ensures precise delivery and maximizes material penetration into the crack.

Vulnerability of Traditional Methods

Traditional methods, such as plastic packers and surface ports, often struggle with backflow prevention. Plastic packers rely on a less rigid seal. This seal can compromise under pressure, allowing material to escape. Surface ports depend on surface adhesion. This adhesion can fail, leading to material leakage around the injection point. These vulnerabilities result in inefficient material delivery and potential waste.

Long-Term Seal Reliability

A repair’s long-term success depends on the durability of its injection point and its contribution to overall structural strength.

Durability of the Injection Point

Steel packers create a highly durable injection point. Their robust construction and high-strength materials resist degradation over time. This ensures the seal remains intact for many years. The injection point maintains its integrity, even under varying environmental conditions.

Contribution to Overall Repair Strength

A reliable seal from a Steel Injection Packer significantly contributes to the overall repair strength. It ensures the injected material fully bonds within the crack. This comprehensive bonding restores the concrete’s structural integrity. It also prevents future water ingress or material deterioration.

Durability of the Injection Point

The injection point’s durability is critical for the repair’s longevity. It must withstand various external and internal stresses.

Robustness Against External Factors

Steel injection packers exhibit exceptional robustness against external factors. They resist physical damage, temperature fluctuations, and environmental stressors. Their sturdy build ensures the injection point remains secure and functional. This resilience protects the repair from premature failure.

Resistance to Chemical Degradation

High-strength steel alloys provide excellent resistance to chemical degradation. These packers withstand exposure to various chemicals present in the concrete or the injected materials. This chemical inertness prevents corrosion or weakening of the packer. It ensures the long-term integrity of the sealed crack.

Direct Comparison: Cost Analysis and Installation Efficiency

Choosing the right crack injection method involves more than just performance. It also requires a thorough cost analysis and an evaluation of installation efficiency. Initial investment, labor, and long-term value all play significant roles in project economics.

Initial Investment vs. Long-Term Value

Project managers must weigh the immediate costs against future benefits. This comparison reveals the true economic impact of each method.

Upfront Material Costs

Traditional methods, like plastic packers and surface ports, typically have lower upfront material costs. Manufacturers produce these items from less expensive materials. This makes them attractive for projects with tight budgets. Steel packers, conversely, involve a higher initial material investment. Their construction uses high-strength steel alloys and specialized components.

Avoiding Rework and Future Repairs

Higher upfront costs for steel packers often translate into significant long-term savings. Their superior pressure resistance and sealing capabilities minimize the risk of repair failure. This reduces the need for costly rework or future repairs. A reliable initial repair prevents additional expenses. It also protects the structure’s integrity over time.

Labor Efficiency and Time Savings

Installation efficiency directly impacts project timelines and labor costs. Different methods require varying levels of effort and skill.

Ease of Installation and Removal

Plastic packers offer quick and easy installation. Workers simply insert and tighten them. Their disposable nature eliminates removal and cleaning time. Steel packers require precise drilling and careful installation. However, their reusability can save time on large, multi-phase projects. Workers can clean and redeploy them.

Skill Level Required for Application

Traditional methods often require less specialized skill for basic applications. This makes them suitable for a broader range of technicians. High-pressure injection with steel packers demands more experienced and skilled labor. Proper installation and operation ensure safety and effectiveness. This expertise contributes to a higher quality repair.

Overall Project Cost Implications

The choice of injection method significantly impacts the total project budget. This applies to both small and large-scale endeavors.

Impact on Large-Scale Projects

For large-scale infrastructure projects, the long-term benefits of steel packers become paramount. Their durability and reliability reduce maintenance costs over the structure’s lifespan. They minimize disruptions from repeated repairs. This leads to substantial overall cost savings for extensive applications.

Considerations for Contractors and Distributors

Contractors benefit from the reliability of steel packers. They experience fewer call-backs and maintain a strong reputation. Distributors can offer these premium solutions to professional construction teams. This provides a high-value option for demanding applications. It also helps them meet the needs of clients seeking durable, long-lasting repairs.

Direct Comparison: Suitability Across Crack Types and Sizes

The effectiveness of a crack injection method often depends on the specific characteristics of the crack. Different crack types and sizes demand varied approaches. Steel injection packers and traditional methods each offer distinct advantages based on these crack properties.

Effectiveness in Hairline Cracks

Hairline cracks present unique challenges due to their narrow openings. The chosen injection method must deliver material precisely and efficiently.

Precision of Injection

Steel injection packers offer superior precision for hairline cracks. Their robust design allows for controlled, high-pressure injection. This ensures the repair material penetrates the narrowest fissures. Traditional plastic packers often struggle with such fine cracks. They may lack the necessary pressure capability to push viscous materials deep into these tiny openings. Surface ports are generally unsuitable for deep hairline cracks. They primarily address surface-level imperfections.

Material Compatibility

Steel packers demonstrate excellent material compatibility for hairline cracks. They effectively inject low-viscosity epoxies and urethanes. These materials are crucial for filling extremely fine cracks. The packer’s secure seal prevents material leakage. This ensures the entire crack receives treatment. Traditional methods may limit material options. Their lower pressure tolerance restricts the use of certain viscous repair compounds.

Performance in Wide and Deep Cracks

Wide and deep cracks require significant material volume and robust delivery. The injection method must ensure complete filling and structural integrity.

Achieving Full Penetration

Steel injection packers excel at achieving full penetration in wide and deep cracks. Their exceptional pressure resistance drives repair materials deep into the concrete. This ensures complete void filling. This capability is vital for structural repairs. Traditional plastic packers often fail to deliver sufficient pressure. This results in incomplete fills in larger cracks. Surface ports are entirely inadequate for deep crack penetration.

Structural Reinforcement Capabilities

Steel packers significantly enhance structural reinforcement in wide and deep cracks. They facilitate the injection of high-strength epoxies. These materials restore the concrete’s load-bearing capacity. The robust injection point itself contributes to the repair’s durability. Traditional methods offer limited structural reinforcement. Their lower pressure and less secure seals compromise the effectiveness of structural materials.

Adaptability to Irregular Crack Geometries

Cracks rarely follow straight lines. Irregular geometries demand flexible and reliable sealing solutions.

Sealing Challenging Cracks

Steel injection packers adapt well to challenging crack geometries. Their specialized sealing mechanisms create a tight seal even in uneven drill holes. This ensures material delivery into complex crack patterns. This adaptability minimizes material waste. Traditional plastic packers may struggle to form a reliable seal in irregular openings. This leads to potential leakage and inefficient repair.

Minimizing Drilling Damage

Steel packers can minimize drilling damage, especially on sensitive substrates. Their relatively thin rubber sealing section allows for reliable expansion in small boreholes. This avoids secondary damage to materials like stone or tiles. This precision is crucial for aesthetic and structural preservation. Traditional packers might require larger drill holes. This increases the risk of damage to delicate surfaces.

Strategic Selection: When to Deploy Each Method

Choosing the correct crack injection method is crucial for project success. This decision depends on various factors. These factors include crack characteristics, project requirements, and desired outcomes. Professionals must carefully evaluate each situation. They then select the most appropriate tools for the job.

Scenarios Demanding Steel Injection Packers

Certain demanding situations specifically call for the robust capabilities of steel injection packers. These tools provide the necessary strength and reliability for critical applications.

Active Water Ingress and High-Pressure Situations

Active water leaks and high-pressure environments require superior sealing and pressure resistance. Steel packers excel in these conditions. They effectively withstand the forces of flowing water and high injection pressures. This ensures the repair material reaches its target without blow-outs or leaks. Their design maintains integrity even when facing constant moisture or aggressive chemicals. This ensures effective sealing and waterproofing.

Structural Concrete Repair Projects

Structural concrete repairs demand lasting integrity. Professionals use steel packers for critical load-bearing elements. These include bridges, parking garages, and industrial foundations. The packers facilitate the injection of high-strength epoxies. These materials restore the concrete’s load-bearing capacity. The robust injection point itself contributes to the repair’s durability.

Large-Scale Infrastructure Applications

Large-scale infrastructure projects benefit significantly from steel packers. These projects often involve extensive concrete structures. They require consistent, high-quality repairs over vast areas. Steel packers provide the reliability and efficiency needed for such undertakings. Their durability reduces maintenance costs over the structure’s lifespan. They minimize disruptions from repeated repairs. This leads to substantial overall cost savings for extensive applications.

When Long-Term Reliability is Paramount

Long-term reliability is a critical factor for many projects. Professionals choose steel packers for permanent solutions. This applies to structural repairs, foundation stabilization, or long-term waterproofing. Durability and reliability over many years are essential. When dealing with critical load-bearing elements, lasting structural integrity is a must. Injected materials must provide lasting support for foundations. They must endure ground movement and structural weight. For extensive concrete restoration in harsh environments, packers must withstand chemicals, moisture, and temperature fluctuations over time. These initiatives aim for permanent fixes.

Optimal Use Cases for Traditional Methods

Traditional crack injection methods offer simplicity and cost-effectiveness. They are ideal for specific, less demanding applications.

Non-Structural Hairline Cracks

Non-structural hairline cracks often do not require high-pressure injection. Plastic packers are the most economical option available for these situations. They allow for low resistance and high-volume product flow. Installation is super-quick. Hammer-in plastic packers create a compression seal rapidly. However, due to a lower friction fit, hammer-in plastic packers have limited injection pressures. These packers are suitable for cosmetic repairs or minor waterproofing.

Budget-Constrained Waterproofing Projects

Budget-constrained waterproofing projects can effectively utilize traditional methods. These methods offer affordable solutions for managing moisture. Interior water drainage systems are less expensive than exterior solutions. They effectively keep basements dry by capturing and rerouting water. Waterproofing paint offers a cost-effective, temporary fix. It reduces humidity levels. Dehumidifiers provide an affordable option to control moisture. Interior sealants are economical for preventing minor dampness. A French drain system is cost-effective when done DIY. It involves digging a trench, laying a perforated pipe, and filling with gravel. Sump pumps are installed in the lowest part of the basement. They pump out collected water. Concrete sealant is easy to apply and affordable for DIY basement waterproofing. Waterproofing primer adheres well to concrete walls. It forms a moisture-resistant layer. Masonry waterproofing paint forms a watertight bond with walls.

DIY Home Repair and Small-Scale Jobs

Homeowners and small contractors often choose traditional methods for DIY home repair and small-scale jobs. These methods are straightforward to apply. They do not require extensive training or specialized equipment. Their ease of use makes them accessible for non-professionals.

Low-Pressure Grouting Applications

Low-pressure grouting applications are well-suited for traditional methods. These applications typically involve filling small voids or sealing minor leaks. The lower pressure tolerance of plastic packers and surface ports is sufficient for these tasks. They effectively deliver low-viscosity materials without the need for high-strength equipment.

Traditional methods offer simplicity and cost-effectiveness for specific applications. However, steel injection packers consistently prove superior for demanding crack injection projects. These projects require high pressure, robust sealing, and long-term durability. The ultimate choice depends on specific crack characteristics, project requirements, and desired outcomes. Professionals carefully assess each situation to ensure optimal repair strategies.

FAQ

What are steel injection packers?

Steel injection packers are robust tools. They deliver repair materials into concrete cracks. Manufacturers make them from high-strength steel alloys. They feature specialized sealing mechanisms. These packers withstand high pressures.

When should one use steel injection packers?

Professionals use steel injection packers for critical structural repairs. They are ideal for active water leaks and high-pressure injections. Large-scale infrastructure projects also benefit. Long-term reliability is paramount in these scenarios.

What are the main advantages of steel packers over plastic packers?

Steel packers offer exceptional pressure resistance. They provide superior sealing capability. They also boast enhanced durability and longevity. Many steel packers are reusable. These features ensure more effective and lasting repairs.

Can one reuse steel injection packers?

Yes, many steel injection packers are reusable. Technicians can clean and inspect them after each use. This reusability reduces waste. It also lowers overall project costs for extensive operations.

Are traditional methods ever better than steel packers?

Traditional methods are suitable for specific, less demanding applications. They work well for non-structural hairline cracks. They are also good for budget-constrained waterproofing projects. DIY home repairs and low-pressure grouting benefit from them.

How do steel packers handle high pressure?

Steel packers are engineered to withstand significant injection forces. They maintain their shape and function under extreme pressure. Their excellent sealing performance improves as pressure increases. This ensures deep penetration of repair materials.

Do steel packers save money in the long run?

Yes, steel packers often lead to long-term savings. Their superior reliability minimizes rework and future repairs. This reduces additional expenses. It also protects the structure’s integrity over time.

Post time: Dec-24-2025