Chemical compatibility stands as the most important factor when selecting an Acrylate Pump for construction. The right pump resists corrosion, handles acrylate resin safely, and ensures reliable performance. This choice protects equipment and supports consistent results throughout every project.

Key Takeaways

- Always check chemical compatibility between the pump materials and acrylate resin to prevent corrosion and leaks, ensuring safe and reliable operation.

- Match the pump’s flow rate and pressure capabilities to your project’s size and needs to optimize resin use and avoid delays.

- Choose pumps that are easy to maintain, durable, and supported by strong supplier training and warranty services to save time, reduce costs, and keep your project on track.

Acrylate Pump Material Compatibility

Is the pump chemically compatible with the acrylate materials I plan to use?

Choosing the right pump for acrylate resin starts with checking chemical compatibility. Acrylate resins can react with certain metals and plastics. If the pump materials do not match the resin, corrosion or leaks may occur. This can lead to equipment failure and project delays.

Engineers should review the pump’s construction. Common materials include stainless steel, PTFE (polytetrafluoroethylene), and specialized elastomers. Each material offers different resistance levels to acrylate chemicals. Stainless steel resists corrosion in many cases. PTFE provides excellent chemical resistance but may cost more.

Tip: Always request a chemical compatibility chart from the pump supplier. This chart shows which materials work best with specific acrylate resins.

Acrylate Pump manufacturers often test their products with a range of chemicals. They publish results in technical datasheets. Reviewing these datasheets helps buyers avoid costly mistakes. Some suppliers also offer sample testing. They can run a compatibility test using the exact resin planned for the project.

A simple checklist can help:

- Identify the acrylate resin type.

- List all pump materials in contact with the resin.

- Compare with the supplier’s compatibility chart.

- Ask for test results or sample testing if unsure.

Selecting a pump with the right materials protects the investment. It also ensures safe and reliable operation on the job site.

Acrylate Pump Flow Rate Requirements

What is the required flow rate for my construction project?

Selecting the correct flow rate stands as a key step when choosing an Acrylate Pump for construction. The flow rate tells how much resin the pump can move in a set time, usually measured in liters per minute (L/min) or gallons per minute (GPM). Every construction project has different needs. Some jobs require fast resin delivery, while others need slow and steady flow.

Project managers should first estimate the total volume of acrylate resin needed for each application. They should also consider the size of the area and the time allowed for pumping. For example, large foundation repairs may need a high flow rate to finish on schedule. Small crack injections may need a lower flow rate for better control.

Tip: Always match the pump’s flow rate to the application. Too high a flow rate can waste material. Too low a flow rate can slow down the project.

A simple table can help compare project needs:

| Application Type | Suggested Flow Rate (L/min) |

|---|---|

| Large slab injection | 20-40 |

| Crack repair | 2-10 |

| Waterproofing | 10-25 |

Engineers should check the pump’s technical datasheet for flow rate ranges. They should also ask the supplier for advice if unsure. Choosing the right flow rate ensures efficient resin use and keeps the project on track.

Acrylate Pump Pressure Capabilities

Can the pump handle the necessary pressure and total head?

Pressure capability stands as a critical factor when selecting a pump for acrylate resin applications. Construction projects often require pumps to move resin through long hoses or up to elevated work areas. Each project has a unique pressure requirement, measured in pounds per square inch (PSI) or bar. If the pump cannot reach the needed pressure, resin flow may slow or stop, causing delays.

Manufacturers design Acrylate Pumps to handle specific pressure ranges. Rotary vane pumps are common in construction. Single-stage rotary vane pumps can reach vacuum levels around 0.15 Torr. Dual-stage models achieve even lower pressures, down to 0.001 Torr. These specifications help users match the pump to the demands of their project.

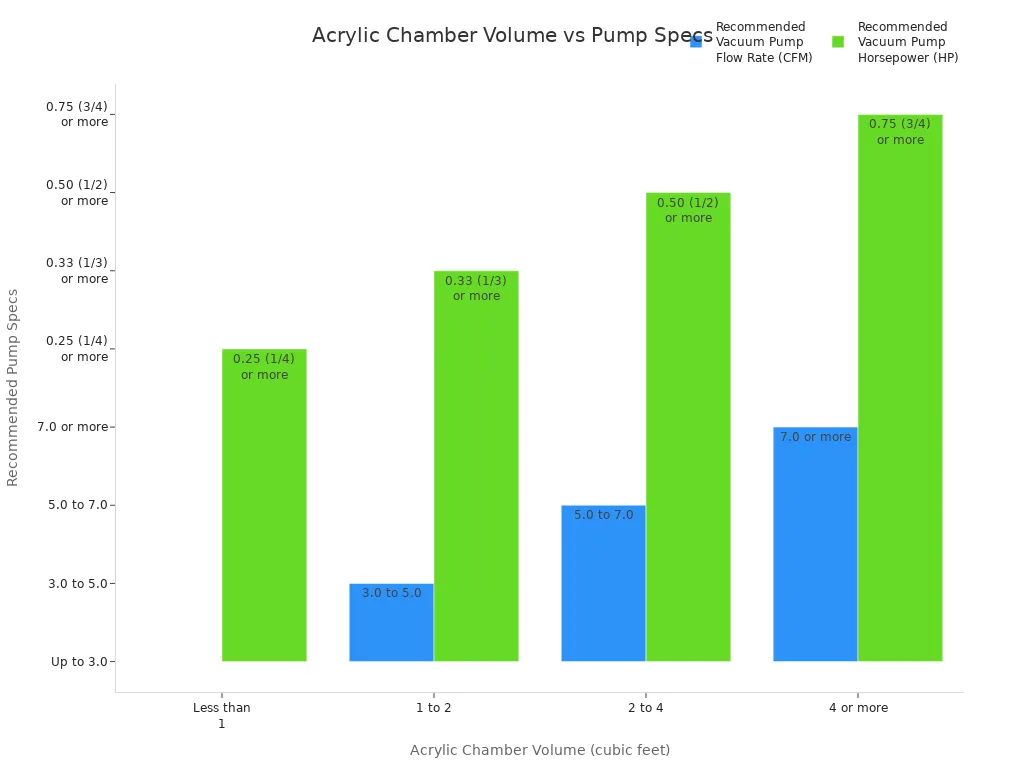

The following table shows recommended vacuum pump flow rates and horsepower for different acrylic chamber volumes:

| Acrylic Chamber Volume (cubic feet) | Recommended Vacuum Pump Flow Rate (CFM) | Recommended Vacuum Pump Horsepower (HP) |

|---|---|---|

| Less than 1 | Up to 3.0 | 0.25 (1/4) or more |

| 1 to 2 | 3.0 to 5.0 | 0.33 (1/3) or more |

| 2 to 4 | 5.0 to 7.0 | 0.50 (1/2) or more |

| 4 or more | 7.0 or more | 0.75 (3/4) or more |

Project managers should check both the maximum pressure and total head the pump can achieve. They should also consider the type of resin, hose length, and elevation. Choosing a pump with the right pressure capability ensures smooth resin delivery and prevents costly interruptions.

Tip: Always consult the pump’s technical datasheet for pressure ratings. Ask the supplier for advice if the project has special requirements.

Acrylate Pump Maintenance and Service

How easy is the pump to maintain and service on-site?

Routine maintenance keeps construction equipment running smoothly. An Acrylate Pump with a simple design allows workers to perform basic service tasks quickly. Pumps with fewer moving parts often require less attention. Clear access to filters, seals, and valves helps technicians complete inspections and replacements without special tools.

Manufacturers often provide maintenance guides with step-by-step instructions. These guides show how to clean and lubricate key components. Some pumps include quick-release fittings or modular parts. These features let workers remove and replace worn pieces in minutes.

Note: Pumps with self-cleaning systems or automatic alerts reduce downtime. These features warn operators about clogs or low lubricant levels.

A maintenance checklist helps teams stay organized:

- Inspect hoses and connections for leaks.

- Clean filters and strainers regularly.

- Check seals for signs of wear.

- Lubricate moving parts as recommended.

- Test the pump after each service.

Training also plays a key role. Suppliers may offer on-site demonstrations or video tutorials. These resources teach workers how to spot problems early and keep the Acrylate Pump in top condition.

Choosing a pump that supports easy maintenance saves time and money. It also reduces the risk of unexpected breakdowns during critical construction phases.

Acrylate Pump Durability and Lifespan

What is the expected durability and operational lifespan of the pump?

Durability plays a major role in the value of any construction equipment. When selecting an acrylate pump, buyers should look for models built with high-quality materials. Stainless steel and PTFE components often last longer than standard plastics or metals. These materials resist wear from harsh chemicals and frequent use.

Manufacturers usually provide an estimated operational lifespan for their pumps. This estimate depends on several factors:

- Frequency of use

- Type of acrylate resin

- Maintenance schedule

- Environmental conditions

A well-maintained pump can last several years, even in tough construction environments. Some suppliers offer pumps with reinforced seals and heavy-duty motors. These features help extend the pump’s service life.

Note: Regular maintenance, such as cleaning filters and checking seals, increases the lifespan of the pump.

Project managers should ask suppliers for data on average pump lifespan. They can also request references from other construction professionals. A reliable acrylate pump reduces downtime and replacement costs.

A simple table can help compare durability features:

| Feature | Benefit |

|---|---|

| Stainless steel parts | Corrosion resistance |

| Reinforced seals | Fewer leaks |

| Heavy-duty motor | Longer operational life |

Choosing a durable pump ensures consistent performance throughout the project.

Acrylate Pump Safety Features

What safety features are included to protect operators and the job site?

Safety remains a top priority on any construction site. Pumps designed for acrylate resin often include several features to protect both operators and the work environment. Manufacturers add these features to reduce risks and prevent accidents.

Many pumps come with automatic shut-off systems. These systems stop the pump if they detect leaks or pressure spikes. This action helps prevent spills and equipment damage. Some models include pressure relief valves. These valves release excess pressure safely, which protects hoses and fittings from bursting.

Grounding connections play an important role. They prevent static electricity buildup, which can ignite flammable vapors. Clear labeling and warning signs on the pump help workers identify hazards quickly. Emergency stop buttons allow operators to halt the pump instantly if a problem occurs.

Tip: Always check for safety certifications, such as CE or UL marks. These certifications show that the pump meets industry safety standards.

A table below highlights common safety features and their benefits:

| Safety Feature | Benefit |

|---|---|

| Automatic shut-off | Prevents spills and overloads |

| Pressure relief valve | Protects against overpressure |

| Grounding connection | Reduces fire risk |

| Emergency stop button | Allows quick shutdown |

Training also supports safety. Suppliers often provide guides or on-site demonstrations. These resources teach workers how to use safety features correctly.

Acrylate Pump Cost Considerations

How much does the pump cost, including installation and ongoing operation?

Cost plays a major role in construction equipment selection. Many buyers focus on the initial purchase price. However, the total cost of ownership often includes much more than the upfront investment. Over time, ongoing operational costs can surpass the original price of the pump.

A chemical industry study shows that the initial purchase cost of a pump usually makes up only 10–20% of the total life cycle cost over ten years. Most expenses come from daily operations and maintenance. These costs include energy use, repairs, and regular servicing.

Peristaltic pumps, for example, require frequent tubing replacement. Maintenance labor, calibration, and spare parts also add to the total expense. These recurring costs can sometimes exceed the initial price. Buyers should balance the upfront investment with these ongoing expenses.

Key ongoing costs include:

- Fuel and labor for daily operation

- Maintenance and parts replacement

- Insurance premiums for equipment and liability

- Storage for unused pumps

- Transportation between job sites

- Financing payments and interest

- Depreciation as the pump ages

- Taxes related to ownership

| Cost Type | Description |

|---|---|

| Initial Purchase | Upfront payment for the pump |

| Operation | Fuel, labor, and energy |

| Maintenance | Parts, servicing, and repairs |

| Insurance | Liability and equipment coverage |

| Storage | Keeping unused pumps secure |

| Transportation | Moving pumps between locations |

| Financing | Loan payments and interest |

| Depreciation | Value loss over time |

| Taxes | Equipment-related taxes |

Tip: Always consider the full life cycle cost, not just the sticker price. This approach helps avoid surprises and supports better budgeting.

Acrylate Pump Supplier Support and Training

What level of technical support and training does the supplier provide?

Supplier support plays a vital role in the success of any construction project. Reliable suppliers offer more than just equipment—they provide expert guidance from the design phase through project completion. This support ensures teams select and install the right injection materials and equipment for each job.

Many suppliers deliver hands-on, component-based technical training. These sessions allow workers to interact with real pump parts, such as mechanical seals and packing. Training often takes place on-site or at the supplier’s facility. Workers can see how to install and test seals under moderate pressure. Clear acrylic seal areas and simulated impeller housings help learners observe pump operation and spot potential issues.

- Training systems often include:

- Installation and testing of mechanical seals and packing

- Leak-off and venting demonstrations

- Industrial-grade components for realistic practice

- Bench or workstation mounting for practical exercises

- Maintenance trainers covering centrifugal pump basics

Note: Practical training helps workers gain confidence and reduces mistakes during real projects.

Suppliers with a local presence can send experienced professionals to the job site. These experts provide timely technical assistance and answer questions as they arise. This level of support helps teams adapt to changing site conditions and maintain pumps correctly. Over time, strong supplier support leads to better pump reliability and longer service life.

A supplier’s commitment to training and support can make a significant difference in project outcomes. Teams that receive proper guidance operate pumps safely and efficiently, reducing downtime and costly repairs.

Acrylate Pump Installation and Integration

Is the pump easy to install and integrate with my current construction setup?

Construction teams often face tight deadlines and complex site conditions. A pump that installs quickly and fits existing systems helps projects stay on schedule. Most modern pumps arrive with clear instructions and labeled parts. Workers can follow step-by-step guides to connect hoses, power sources, and control panels.

Manufacturers design many pumps with modular components. These parts snap or bolt together without special tools. Quick-connect fittings allow teams to attach hoses in minutes. Some models feature adjustable mounting brackets. These brackets help the pump fit into tight spaces or onto uneven surfaces.

Tip: Before installation, review the site layout and check for enough space around the pump. This step prevents problems during setup and future maintenance.

Integration with current equipment matters. Pumps that use standard hose sizes and electrical connections reduce the need for extra adapters. Digital control panels often support common protocols, making it easier to link the pump with monitoring systems.

A checklist for smooth installation:

- Unpack and inspect all parts

- Position the pump on a stable surface

- Connect hoses and power supply

- Test for leaks and proper operation

- Train workers on basic controls

Teams that plan ahead and choose user-friendly pumps save time and avoid costly mistakes. Proper installation ensures safe and efficient operation from day one.

Acrylate Pump Warranty and After-Sales Service

What warranty and after-sales service options are available?

Warranty and after-sales service play a crucial role in construction equipment decisions. Buyers should always review the warranty terms before making a purchase. Most manufacturers offer a standard warranty that covers defects in manufacturing, materials, and workmanship. This coverage gives buyers peace of mind and protects their investment.

The typical warranty lasts for one year from the date of purchase. Both residential and commercial users receive this protection. To claim warranty service, buyers must provide proof of purchase. The warranty does not cover every issue. Problems caused by chemical alteration, over voltage, or physical damage during transport fall outside the warranty. Opened or modified parts, as well as components affected by water quality or chemical residues, also remain excluded.

Here is a summary of standard warranty terms:

| Warranty Aspect | Details |

|---|---|

| Coverage | Defects in manufacturing, material, and workmanship |

| Duration | 1 year from date of purchase by original owner/end-user |

| Applicable Use | Both residential and commercial |

| Proof of Purchase | Required |

| Warranty Exclusions | Chemical alteration, over voltage, transport or impact damage, opened or modified parts, components altered by water quality or chemicals, wet-end blockage by residues (e.g., hair) |

After-sales service often includes technical support, spare parts availability, and repair services. Many suppliers provide phone or online support to help with troubleshooting. Some companies offer on-site repairs or maintenance visits. Quick access to spare parts reduces downtime and keeps projects moving forward.

Tip: Always ask the supplier about the process for warranty claims and the availability of after-sales support. Reliable service can make a big difference during critical construction phases.

Making the Right Acrylate Pump Choice

How to prioritize your requirements for an acrylate pump

Every construction project has unique needs. Project managers should start by listing their most important requirements. Safety and chemical compatibility often come first. These factors protect workers and equipment. Next, teams should consider flow rate and pressure. These features help match the pump to the job’s size and speed. Maintenance and durability also matter. Pumps that last longer and need less service save money over time.

Budget plays a key role. Teams should set a clear spending limit before comparing models. They should also think about installation and training. Pumps that are easy to set up and use can help projects finish on time. Teams should talk with suppliers to learn about support and warranty options. This step helps avoid problems later.

Tip: Write down your top three must-have features. Use this list to guide your search and avoid distractions from less important details.

Tips for comparing different acrylate pump models

When comparing pump models, teams should look at several features side by side:

- Ultimate vacuum level and pump flow rate

- Pump power and quality

- Duty cycle and vacuum system needs (such as oil-free operation)

- Connection hardware and ease of integration

- Maintenance requirements and noise levels

- Exhaust emissions and operational costs

- Budget range and expected lifespan

Understanding pump types is important. Dual-stage rotary vane pumps reach deeper vacuums and work more efficiently but need oil and can be noisy. Aspirator pumps are simple and oil-free but cannot achieve high vacuums. Teams should match the pump’s flow rate to the chamber volume and target vacuum level for best results.

A table can help organize the comparison:

| Feature | Model A | Model B |

|---|---|---|

| Vacuum Level | 0.001 Torr | 80 Torr |

| Oil-Free Operation | No | Yes |

| Noise Level | High | Low |

| Price Range | $1,500–$15,000 | $100–$1,000 |

Note: Always check for hidden costs, such as maintenance or special installation needs. These can affect the total value of the pump.

Asking the right questions helps buyers choose the best Acrylate Pump for construction. Industry leaders recommend these next steps:

- Verify all connections and check for leaks.

- Test pump operation and measurement tools.

- Match the pump’s duty rating to project needs.

Consulting experts ensures the best fit for every job.

FAQ

What type of acrylate resin works best with most pumps?

Most pumps handle standard methyl methacrylate resins well. Always check the pump’s compatibility chart before selecting a resin for your project.

How often should technicians inspect an acrylate pump during use?

Technicians should inspect the pump daily during active use. Regular checks help prevent leaks, clogs, and unexpected downtime on the job site.

Can one pump handle multiple acrylate resin types?

Some pumps support different resin types. Always confirm with the supplier and review technical datasheets to ensure safe and reliable operation.

Post time: Jul-18-2025