Singapore’s unique climate demands robust waterproofing solutions. Identifying the most effective High Pressure Injection Pump is crucial for project success. Professionals require an Injection Pump with specific features for local conditions. Durability and precision define a top-rated unit. Reliable equipment, including a suitable Steel Injection Packer, ensures successful waterproofing outcomes. This equipment prevents structural damage and maintains building integrity in Singapore.

Key Takeaways

- Singapore’s climate needs strong waterproofing. High humidity and heavy rain cause fast damage to buildings.

- High-pressure injection pumps fix leaks. They protect buildings from water damage and make them last longer.

- Good pumps must be strong. They need to resist rust and work with different sealing liquids like PU foam.

- The Graco Xtreme NXT pump is powerful. It works well for big jobs like basement waterproofing.

- The DeWalt DWP611 pump is small and easy to move. It is good for fixing small cracks and quick repairs.

- Special grout pumps handle large areas. They seal big projects like tunnels very fast.

- The Selleys PP-09 pump is light and portable. It works for many tasks like sealing cracks and grouting.

- Always clean your pump after use. Store it in a dry place to make it last longer in Singapore’s weather.

Understanding High-Pressure Injection for Singapore’s Environment

High-pressure injection technology offers crucial solutions for waterproofing challenges in Singapore. This method effectively addresses the unique environmental conditions prevalent in the region. It ensures the longevity and integrity of various structures.

Why High-Pressure Injection is Essential for Singapore’s Climate

Addressing High Humidity and Rainfall

Singapore experiences consistently high humidity and significant rainfall throughout the year. The average relative humidity remains around 84% year-round. Daily ranges often fluctuate between 65% and 95%. Temperatures average 27.8°C, with daily highs reaching 33°C. The annual rainfall totals 2,165mm. These conditions create a constant moisture presence. Even with intermittent air conditioning, HDB bedrooms typically maintain 70-80% humidity. This persistent moisture necessitates robust waterproofing methods.

Combating Rapid Deterioration of Structures

The high humidity and temperature accelerate material degradation. This rapid deterioration affects various building components. Consider the impact on common materials:

| Feature / Material | Aluminium Wardrobe | Wooden Wardrobe (e.g., MDF with melamine) |

|---|---|---|

| Moisture Absorption | 0% (non-porous) | Up to 14% weight increase (hygroscopic) |

| Dimensional Change | 0.1mm (thermal expansion only) | 2-4mm across joints, visible swelling |

| Mould Growth | Zero over 24 months | Appears within 6-8 months on untreated surfaces |

| Structural Integrity (85% humidity) | Maintained | Warping, joint loosening within 6-8 months |

| Temperature Cycling Effects | Minimal expansion/contraction (0.1-0.2mm), hardware secure, no delamination, stable alignment | Loosens screw holes, veneer bubbling/peeling, door alignment changes, gaps in joints |

These findings, from the Building and Construction Authority and Building Research Institute Singapore, highlight the vulnerability of structures. High-pressure injection provides a proactive defense against such rapid deterioration.

Key Features of High Pressure Injection Pumps for Singaporean Projects

Optimal Pressure and Flow Rate Requirements

Effective waterproofing in Singapore demands specific pump capabilities. High Pressure Injection Pump models must deliver optimal pressure and flow rates. These parameters ensure deep penetration of sealing materials into cracks and voids. Sufficient pressure overcomes structural resistance. An adequate flow rate allows for efficient material delivery.

Durability and Corrosion Resistance in Tropical Climates

Tropical climates are harsh on equipment. Pumps must withstand high humidity and heat. Manufacturers design durable pumps with corrosion-resistant components. This ensures reliable operation and extends equipment lifespan. Materials like stainless steel or specialized coatings protect against environmental wear.

Compatibility with Common Waterproofing Resins

Pumps must handle various waterproofing resins. Polyurethane (PU) is a common choice. It is a fluid resin injected into cracks and voids in concrete structures. Upon injection, it chemically transforms from a liquid to a solid within minutes. Its short curing time makes it ideal for sealing active leaks. Its low viscosity allows it to seal tiny cracks after curing on moisture. Post-injection, polyurethane cures and retains flexibility. It accommodates structural movement while keeping voids sealed and preventing leaks.

The injection process involves several steps:

- A hole is drilled on the underside of the ceiling.

- Polyurethane foam is injected using a pressure machine.

- The pressure causes the polyurethane to ascend into cracks or voids caused by water damage.

- The polyurethane expands to fill these cracks and voids.

Two main types of PU resins exist:

- Hydrophilic PU Resin: This reacts with water and expands to form a soft, flexible foam. It suits fine cracks and minor seepage.

- Hydrophobic PU Resin: This is designed for larger cracks or high-flow leaks. It forms a rigid, closed-cell foam highly resistant to water infiltration.

High-pressure injection pumps are specifically used for PU resin injection. Pumps must also accommodate epoxy resins and acrylic gels.

Portability and Ease of Use on Singaporean Job Sites

Singaporean job sites often have limited space. Portability is a significant advantage for equipment. Lightweight and compact pumps allow easy transport between different areas. User-friendly designs reduce training time. They also minimize operational errors. This enhances overall project efficiency.

Top-Rated High Pressure Injection Pumps for Singapore

Graco Xtreme NXT: A Robust High Pressure Injection Pump Solution

Key Specifications and Performance Metrics

The Graco Xtreme NXT series represents a pinnacle in high-pressure fluid handling. These pumps feature air motors designed for extreme conditions, delivering consistent pressure and flow rates. They offer various pressure ratios, often reaching up to 7,250 psi (500 bar) for material delivery. Their robust construction allows them to handle highly viscous materials, making them suitable for demanding waterproofing applications. The pump’s design prioritizes efficiency, minimizing material waste and maximizing output.

Advantages for Singapore Projects: Durability and Versatility

Graco Xtreme NXT pumps offer significant advantages for Singapore’s challenging environment. Their heavy-duty construction provides exceptional durability, resisting wear and tear from continuous operation and harsh job site conditions. The corrosion-resistant components ensure longevity, even with exposure to high humidity and aggressive waterproofing chemicals. Their versatility allows them to handle a wide range of materials, from thin resins to thick grouts, making them adaptable to various project requirements. This adaptability reduces the need for multiple specialized pumps.

Ideal Applications: Large-Scale Basement and Structural Waterproofing

These pumps excel in large-scale waterproofing projects. Contractors frequently deploy them for extensive basement waterproofing, where high volumes of material and sustained pressure are necessary. They are also ideal for structural waterproofing, including sealing large cracks in concrete foundations, tunnels, and retaining walls. Their power and reliability ensure effective penetration and sealing, providing long-lasting protection against water ingress in critical infrastructure.

DeWalt DWP611: Precision and Portability in High Pressure Injection

Key Specifications and Operational Details

The DeWalt DWP611, while primarily a compact router, can be adapted for specific high-pressure injection tasks due to its powerful motor and precise control. When configured for injection, it typically operates with a motor delivering around 1.25 horsepower, providing sufficient power for smaller-scale injection applications. Its variable speed control allows operators to adjust the flow rate and pressure, offering precision for delicate work. The unit’s lightweight design, often around 4.5 pounds, enhances its portability.

Advantages for Singapore Projects: Maneuverability and Cost-Effectiveness

The DeWalt DWP611 offers distinct advantages for Singaporean projects requiring maneuverability. Its compact size and light weight make it exceptionally easy to transport and operate in confined spaces, common on urban job sites. This portability reduces setup time and allows technicians to access difficult-to-reach areas efficiently. Furthermore, its relatively lower initial cost compared to industrial-grade pumps makes it a cost-effective solution for smaller businesses or projects with budget constraints. It provides a reliable option for targeted repairs without a large capital investment.

Ideal Applications: Crack Injection and Smaller Repair Jobs

This adapted tool is particularly well-suited for precise crack injection and smaller repair jobs. Technicians use it for sealing hairline cracks in concrete, repairing localized leaks in bathrooms or balconies, and addressing minor seepage issues. Its precision control allows for targeted material application, minimizing waste and ensuring effective sealing in specific problem areas. It serves as an excellent choice for maintenance work and quick, localized waterproofing interventions.

Specialized Grout Pump Models: High-Volume High Pressure Injection Performance

Key Specifications for High-Volume Output

Specialized grout pumps are engineered for high-volume, high-pressure injection tasks. These pumps deliver substantial output, crucial for extensive waterproofing projects.

| Feature | Specification |

|---|---|

| Max Pressure | Up to 150 bar |

| Flow Rate | 1.0 – 3.5 L/min |

Another common specification for these powerful units includes:

| Specification | Value |

|---|---|

| Max. Output Pressure | 13500 Psi |

| Flow | 0-1.5 L/min |

These specifications highlight their capability to handle large quantities of material under significant pressure, ensuring deep penetration and thorough sealing.

Advantages for Singapore Projects: Efficiency for Extensive Areas

These specialized grout pumps offer unparalleled efficiency for extensive waterproofing areas. Their high flow rates and pressure capabilities allow for rapid material application over large surfaces, significantly reducing project timelines. This efficiency is particularly beneficial for large commercial buildings, infrastructure projects, and extensive basement waterproofing where time is a critical factor. The ability to deliver consistent, high-volume output ensures uniform material distribution and effective sealing across vast areas.

Ideal Applications: Curtain Grouting and Large-Scale Sealing

Specialized grout pumps are the preferred choice for curtain grouting, a method used to create an impermeable barrier around structures. They are also ideal for large-scale sealing operations in tunnels, dams, and underground structures. Their robust design and high performance make them indispensable for projects requiring comprehensive and durable waterproofing solutions over extensive areas. A High Pressure Injection Pump of this caliber ensures long-term structural integrity.

Selleys PU Injection Pump PP-09: A Portable High Pressure Injection Option

Key Specifications and Unique Selling Points (10000 psi output, 900W motor)

The Selleys PU Injection Pump PP-09 stands out as a highly portable and efficient solution for various waterproofing needs. This compact unit delivers impressive performance for its size. It achieves an output pressure of 10000 psi (700 bar), ensuring deep penetration of injection materials. The pump features a re-start pressure of less than 7500 psi (520 bar), allowing for consistent operation. A robust 900 W (1.2 hp) motor powers the unit, operating on a standard 220 V / 50 Hz electrical supply. It handles materials with a maximum grain size of 0-2 mm. The entire unit weighs only 7 kg, making it exceptionally easy to transport and maneuver on job sites.

| Attribute Name | Value |

|---|---|

| Output Pressure | 10000 psi / 700 bar |

| Re-start Pressure | < 7500 psi / 520 bar |

| Motor Rating | 900 W / 1.2 hp |

| Voltage | 220 V / 50 Hz |

| Max. Grain Size | 0 – 2 mm |

| Weight | 7 kg |

Advantages for Singapore Projects: Portability and Multi-Purpose Use

The Selleys PU Injection Pump PP-09 offers significant advantages for waterproofing projects in Singapore. Its small size, light weight, and easy handling make it highly portable. Technicians can effortlessly move the pump across different areas of a job site, including confined spaces common in urban environments. This portability reduces setup time and increases operational efficiency. The pump’s multi-purpose capabilities further enhance its value. It performs effectively for PU injection, PU grouting, and general crack repair. This versatility means contractors often need only one High Pressure Injection Pump for a range of tasks, streamlining equipment management and reducing overall costs.

Ideal Applications: PU Injection, Grouting, and Crack Repair

The Selleys PU Injection Pump PP-09 is ideal for a wide array of waterproofing applications. It excels in PU injection for sealing leaks in concrete structures. Its capabilities extend to PU grouting, which creates a waterproof barrier in various construction elements. The pump effectively handles general crack repair in buildings, ensuring structural integrity. It finds common use in underground concrete works, where precise and powerful injection is crucial. Furthermore, technicians utilize it for sealing expansion and structural joints, preventing water ingress. The pump also provides an effective solution for tunnel leakage, maintaining the dryness and safety of subterranean passages.

Factors for Selecting the Right High Pressure Injection Pump in Singapore

Choosing the correct High Pressure Injection Pump is crucial for successful waterproofing projects in Singapore. Several factors influence this decision, ensuring optimal performance and cost-effectiveness.

Matching High Pressure Injection Pump to Project Scale and Type

Project scale and type significantly dictate pump selection. Different demands arise from varying project sizes and complexities.

Residential vs. Commercial Project Demands

Residential projects often require smaller, more portable pumps for localized repairs. These pumps offer maneuverability in confined spaces. Commercial projects, conversely, demand robust, high-capacity pumps. These larger units handle extensive areas and continuous operation. They ensure efficient material delivery for large-scale waterproofing.

Crack Repair vs. Extensive Leak Sealing

Crack repair typically involves precise, lower-volume injection. Smaller pumps with adjustable pressure controls are suitable for this task. Extensive leak sealing, such as curtain grouting, requires high-volume output and sustained pressure. Specialized grout pumps excel in these demanding applications, covering large areas effectively.

Compatibility with Injection Materials for High Pressure Injection

The type of injection material used directly impacts pump compatibility. Each material has specific viscosity and curing properties.

Polyurethane (PU) Foam Applications

Pumps for polyurethane (PU) foam must handle its reactive nature. PU foams expand upon contact with water, sealing leaks rapidly. The pump needs to deliver consistent pressure to ensure deep penetration before the material cures.

Epoxy Resin Injection Requirements

Epoxy resins are typically two-part systems. They require pumps capable of mixing and injecting viscous materials. Epoxy pumps must maintain precise ratios for proper curing and strong adhesion. These resins are ideal for structural crack repair.

Acrylic Gel Suitability

Acrylic gels are water-based and have low viscosity. Pumps for acrylic gels need to handle these thinner materials without excessive pressure. Acrylic gels form a flexible, waterproof barrier, suitable for various sealing applications.

Budgetary Considerations and Return on Investment for High Pressure Injection Pumps

Financial planning plays a vital role in equipment procurement. Contractors must balance initial costs with long-term benefits.

Initial Purchase Cost vs. Long-Term Value

The initial purchase cost for a High Pressure Injection Pump varies widely. For instance, a Denso 294050-0060 injection pump for a John Deere S450 has a price “on request.” The cost of fuel injection pump parts also varies depending on the specific part and engine model. Customers should contact sales teams directly for accurate quotes. While some pumps have higher upfront costs, their long-term value often outweighs this initial expense.

Operational Efficiency and Material Savings

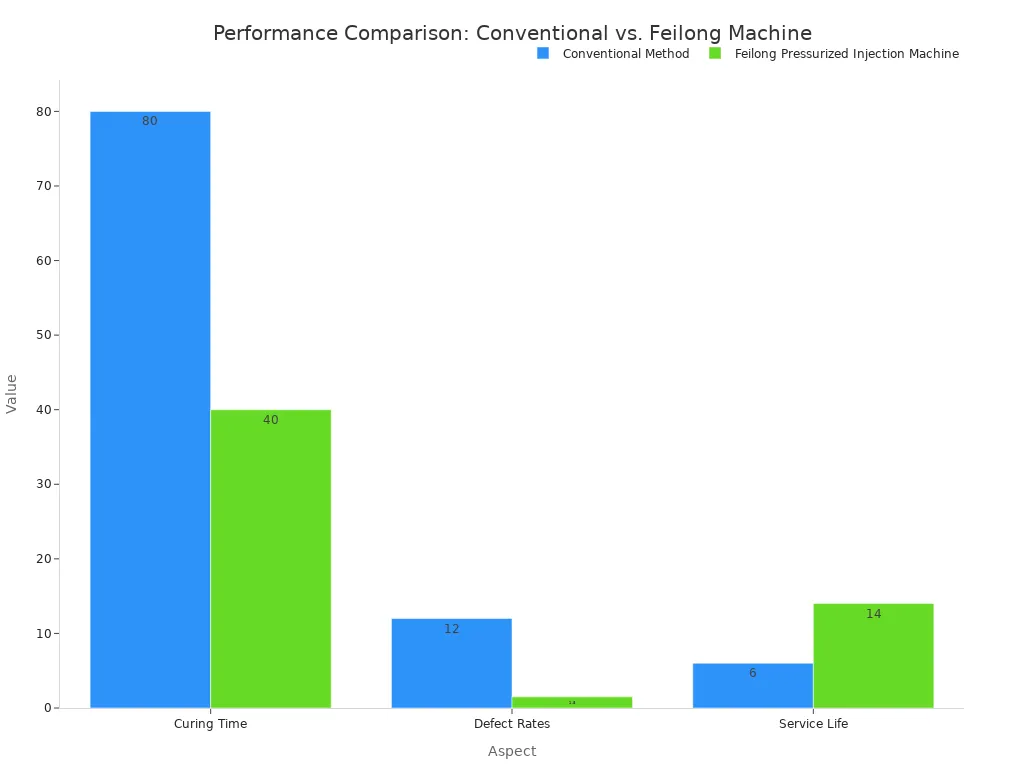

High-pressure injection pumps contribute to long-term value through operational efficiency and material savings. Consider the Feilong Pressurized Injection Machine:

| Aspect | Conventional Method | Feilong Pressurized Injection Machine |

|---|---|---|

| Curing Time | 80 minutes | 40 minutes (50% faster) |

| Defect Rates | 12% | 1.5% |

| Service Life | 6 years | 14 years (2.3x longer) |

These pumps offer significant advantages:

- Operational Efficiency: They operate free of manual intervention, saving labor and maintenance costs. They maintain accurate, stable flow rates, reducing frequent adjustments. This results in a virtually maintenance-free platform and a 30 to 40% cost reduction over conventional chemical injection systems.

- Material Savings: Stable chemical injection rates prevent overdosing, leading to chemical cost savings. Conventional systems often overdose by 10-20%. Adequate chemical prevalence also preserves assets, avoiding damage from underdosing.

Local Support and Spare Parts Availability for High Pressure Injection Pumps

Accessible local support and readily available spare parts are paramount for maintaining operational efficiency in Singapore’s demanding waterproofing industry. Equipment downtime directly impacts project timelines and profitability. Therefore, contractors prioritize suppliers offering robust after-sales services.

Importance of Accessible Maintenance Services

Reliable maintenance services ensure the continuous operation of specialized waterproofing equipment. Local support teams provide swift technical assistance, minimizing disruptions on job sites. Winston Engineering, for example, offers comprehensive support for chemical injection pumps. Their services include certified installation, commissioning, and emergency responses. Operating from their Regional Headquarters in Singapore, they guarantee a swift technical response for clients across Singapore and Southeast Asia. This localized presence means technicians can quickly diagnose and resolve issues, preventing prolonged project delays. Regular servicing by certified professionals also extends the lifespan of equipment, protecting significant investments.

Ensuring Quick Access to Replacement Parts

Prompt access to replacement parts is equally critical for efficient project execution. Even with diligent maintenance, components eventually wear out. A local supplier with a well-stocked inventory of spare parts can provide replacements quickly, avoiding lengthy waits for international shipments. This rapid availability prevents equipment from sitting idle, which saves contractors time and money. To maximize equipment longevity and reduce unexpected part failures, operators should regularly check seals, valves, and O-rings for wear or leakage. They must also ensure proper lubrication where applicable. Using clean, filtered water, free from debris, helps prevent internal damage. Following the manufacturer’s guidelines for pump overhaul or parts replacement intervals further ensures optimal performance and reduces the need for emergency repairs. This proactive approach, combined with accessible local parts, keeps projects on schedule.

Maximizing High Pressure Injection Pump Longevity in Singapore’s Environment

Ensuring the longevity of waterproofing equipment is crucial for sustained project success in Singapore’s challenging climate. Proper care and maintenance protocols significantly extend the lifespan of injection pumps. This section outlines essential practices for maximizing equipment durability.

Essential Cleaning and Maintenance Protocols for High Pressure Injection Pumps

Regular cleaning and maintenance are fundamental to preventing equipment failure and maintaining optimal performance. These procedures vary based on the materials used.

Post-Use Cleaning Procedures for Different Materials

Thorough cleaning immediately after use prevents material hardening and component damage. Upon completion of injection, technicians must clean all tools and equipment that have contacted the resin. They should use DE NEEF® Washing Agent for this task. Perform this cleaning within 30 minutes of finishing the injection. Operators must not leave the pump filled with resin overnight or for periods exceeding one work shift. Avoiding solvents or other cleaning products is important. These alternatives are less effective and can pose safety risks.

Preventing Clogging and Material Build-up

Consistent cleaning prevents clogging and material build-up within the pump’s internal components. Flushing the system with appropriate cleaning agents after each use removes residual materials. Regular inspection of filters and nozzles also helps identify and clear any blockages before they become severe. This proactive approach ensures smooth operation and reduces wear on moving parts.

Proper Storage Techniques for High Pressure Injection Pumps in Tropical Climates

Singapore’s tropical climate presents unique challenges for equipment storage. High humidity and temperatures can accelerate degradation.

Protecting Against Humidity and Corrosion

Humidity is a primary concern for metal components. Storing pumps in a dry, climate-controlled environment minimizes moisture exposure. Applying corrosion-inhibiting sprays or coatings to exposed metal parts provides an additional layer of protection. This practice prevents rust formation, which can compromise structural integrity and functionality.

Recommended Storage Conditions

Store injection pumps in a clean, dry area away from direct sunlight and extreme temperatures. Covering the equipment with a protective tarp or cover shields it from dust and environmental contaminants. Disconnecting and properly storing hoses and accessories also prevents damage and extends their usability.

Common Troubleshooting and Preventative Measures for High Pressure Injection Pumps

Understanding common issues and implementing preventative measures can significantly reduce downtime and repair costs.

Addressing Pressure Fluctuations

Pressure fluctuations can indicate several underlying problems. Mobile phase degassing can cause pressure instability. Technicians should check and replace damaged one-way valves and pumps. Mobile phase viscosity changes can also lead to pressure fluctuations; using solvent gradient elution can help. Leakage at the joint often causes pressure drops. Tightening, cleaning, or replacing the joint can resolve this. Pump leakage also contributes to pressure issues. Technicians should check for loose check valves or joints and tighten them if necessary. They must also inspect the mixer and pump seals for damage.

| Problem (leading to pressure drop or low pressure) | Troubleshooting Steps |

|---|---|

| Insufficient pump flow | Empty the mobile phase container and replace the on-line filter head of the sample inlet in the container. Check if the pipeline is squeezed. Check traffic settings. System-wide leak detection. |

| Pump check valve or gasket leakage | Replace or clean the check valve. Replace the pump gasket. Check for residue from salting out. |

| Bubbles in the pump | Solvent degassing. Check whether the pipeline from the solvent bottle to the pump is blocked. Replace the in-line filter head of the injector. |

Resolving Material Flow Issues

Material flow problems often stem from blockages or incorrect settings. Ensure the material is properly mixed and free of lumps before loading. Check hoses and nozzles for obstructions. Adjusting pump settings, such as pressure and flow rate, can optimize material delivery. Regular cleaning of the material reservoir also prevents contaminants from entering the system.

Selecting the appropriate high-pressure injection pump remains critical for Singapore’s waterproofing projects. Top-rated models, including the robust Graco Xtreme NXT and the precise DeWalt DWP611, offer distinct benefits. Specialized grout pumps provide high-volume efficiency, while the Selleys PP-09 ensures excellent portability. Informed decision-making guarantees successful and durable waterproofing outcomes. Professionals achieve lasting protection against Singapore’s challenging climate by carefully choosing the right equipment.

FAQ

What makes high-pressure injection crucial for Singapore’s climate?

High humidity and heavy rainfall accelerate structural deterioration. High-pressure injection creates robust, long-lasting seals. This method prevents water ingress effectively. It protects buildings from rapid degradation in the tropical environment.

Which high-pressure injection pump suits large-scale waterproofing projects?

The Graco Xtreme NXT series is ideal for large projects. It offers high pressure and flow rates. This pump handles extensive basement and structural waterproofing efficiently. Its robust design ensures durability for demanding tasks.

Which pump is best for precise crack injection and smaller repairs?

The DeWalt DWP611, when adapted, provides precision and portability. It excels in sealing hairline cracks and localized leaks. Its compact size allows easy maneuverability in confined spaces. This makes it cost-effective for targeted interventions.

What types of waterproofing materials do these pumps handle?

High-pressure injection pumps handle various materials. They commonly work with polyurethane (PU) foam, epoxy resins, and acrylic gels. Each material serves specific waterproofing needs. Pumps must be compatible with the chosen resin’s viscosity and properties.

How can I maximize my injection pump’s lifespan in Singapore’s environment?

Regular cleaning and proper storage are essential. Clean all components immediately after use. Store the pump in a dry, climate-controlled area. This protects it from humidity and corrosion. Following maintenance protocols prevents clogging and extends equipment life.

Why is local support important for high-pressure injection pumps in Singapore?

Local support ensures quick access to maintenance services. It also provides readily available spare parts. This minimizes equipment downtime. Swift technical assistance and parts availability keep projects on schedule. It reduces overall operational costs.

What are the advantages of specialized grout pumps for extensive areas?

Specialized grout pumps offer high-volume output and sustained pressure. They efficiently cover large surfaces. This reduces project timelines for extensive waterproofing. These pumps are ideal for curtain grouting and large-scale sealing in infrastructure projects.

Post time: Dec-02-2025