Steel injection packers offer superior durability and sealing capabilities. They are a preferred choice for demanding injection applications. Their robust construction ensures reliability and consistent performance. This robust design is crucial where other packer types may fall short. A Steel Injection Packer provides effective results in various challenging environments. Professionals rely on their proven strength.

Key Takeaways

- Steel injection packers are very strong tools. They create a temporary seal in a drilled hole.

- These packers handle high pressure. They can withstand over 400 bar of pressure.

- Steel packers last a long time. They resist damage from impacts and bad weather.

- They make a tight seal. This stops injected materials from leaking out.

- Steel packers work well with many chemicals. They do not break down from harsh materials.

- They perform well in all temperatures. They stay strong in hot or cold conditions.

- You can often use steel packers more than once. This saves money on projects.

Understanding the Fundamentals of Steel Injection Packers

Defining Injection Packers

Basic Function and Purpose

Injection packers are essential tools in construction and repair. They create a temporary seal within a drilled hole. This seal allows for the controlled injection of various materials. Workers use them to deliver resins, grouts, or other sealants into cracks, voids, or soil. Their primary purpose is to ensure the injected material reaches its target area effectively. They also prevent material leakage back out of the hole. This controlled delivery is critical for successful repair and stabilization projects.

Key Components and Materials

An injection packer typically consists of several key components. It has a main body, often threaded, which fits into the drilled hole. A sealing element, usually rubber or a similar compressible material, expands to create the seal. A valve or port allows the injection material to enter. Different materials construct packers, including plastic, aluminum, and steel. Each material offers distinct properties for specific applications. For instance, cement packers can be made of steel (screwed) or plastic (driven). They feature a large flow diameter, enabling the injection of materials with higher density or larger grain size.

Distinguishing Steel Injection Packers

Material Composition and Strength

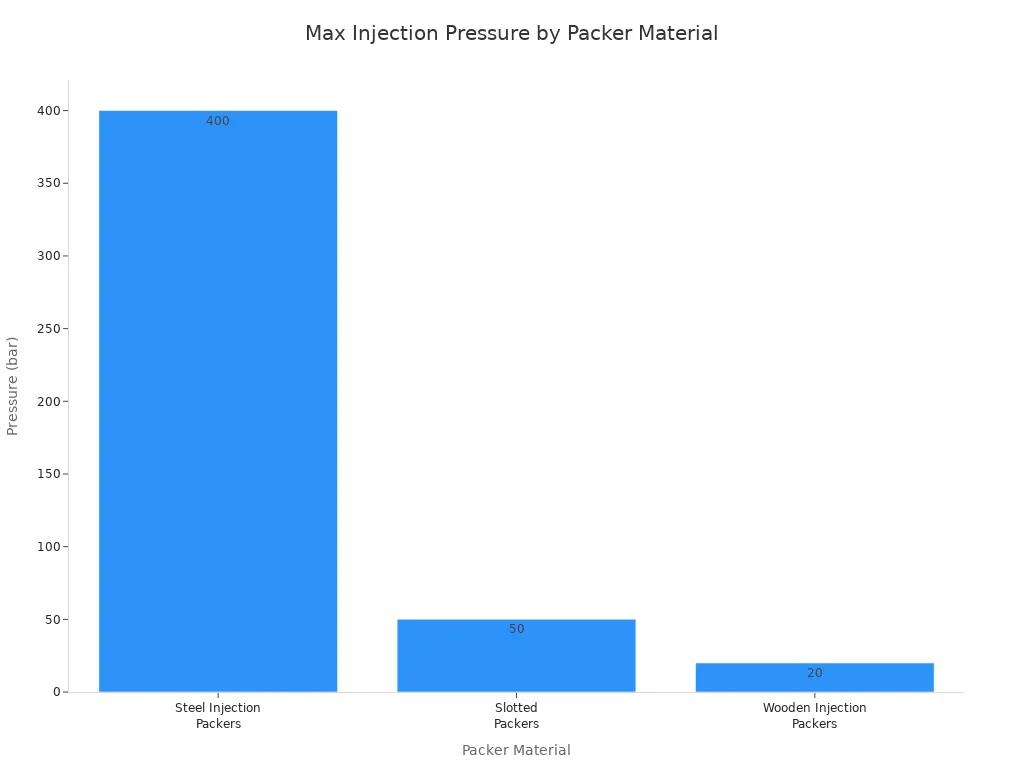

Steel injection packers stand out due to their robust material composition. Manufacturers craft them from high-grade steel alloys. These alloys provide exceptional tensile strength and rigidity. This inherent strength allows them to withstand significant forces during injection. Other materials cannot match steel’s ability to endure extreme pressures. The following table illustrates the maximum injection pressure different packer materials can handle:

| Packer Material | Maximum Injection Pressure |

|---|---|

| Steel Injection Packers | Above 400 bar |

| Slotted Packers | 50 bar |

| Wooden Injection Packers | Up to 20 bar |

This chart further visualizes the pressure resistance:

Initial Performance Characteristics

From the moment of installation, a Steel Injection Packer demonstrates superior performance. Its rigid structure ensures a tight, immediate seal. This rigidity prevents premature material bypass or blow-out. The high strength of steel means the packer maintains its integrity even under initial high-pressure surges. This reliability is crucial for starting injection processes smoothly and efficiently. It minimizes the risk of early failures and ensures consistent material delivery.

Core Advantages of Steel Injection Packers

Superior Durability and Strength

Resistance to High Pressures

Steel injection packers offer exceptional resistance to high pressures. Their robust construction prevents deformation or failure under extreme injection forces. This inherent strength ensures the packer maintains its integrity throughout the injection process. It effectively prevents material blow-outs, even when injecting viscous grouts or resins at significant pressures. This capability is critical for successful and safe operations in demanding environments.

Impact and Environmental Resilience

Steel packers demonstrate remarkable resilience against physical impacts and harsh environmental conditions. Construction sites often present challenging scenarios with potential for accidental damage. Steel withstands abrasions, impacts, and general wear and tear far better than alternative materials. Furthermore, steel resists degradation from exposure to moisture, temperature fluctuations, and other environmental stressors. This resilience ensures consistent performance and a longer service life in diverse settings, from underground tunnels to exposed outdoor structures.

Enhanced Sealing Integrity

Rigidity for Reliable Seals

The inherent rigidity of steel ensures superior sealing integrity. A Steel Injection Packer maintains its precise shape, allowing the sealing element to expand uniformly against the bore of the drilled hole. This consistent pressure creates a tight, reliable seal. Less rigid materials can deform under pressure, leading to inconsistent seals and potential leakage. Steel’s stability guarantees that injected materials reach their intended target without bypass.

Long-Lasting Sealing Performance

Steel’s durability directly contributes to long-lasting sealing performance. The packer’s robust body resists wear and tear from repeated use and prolonged exposure to injection pressures. This longevity means the seal remains effective throughout the entire injection process, from start to finish. It also allows for potential reusability in certain applications, further enhancing cost-efficiency. The consistent performance minimizes the need for re-drilling or re-injection, saving time and resources.

Chemical Resistance

Withstanding Aggressive Injection Materials

Steel injection packers exhibit excellent resistance to aggressive injection materials. Many resins, grouts, and chemical sealants contain corrosive components. Steel’s material composition allows it to withstand these harsh chemicals without corroding or degrading. This resistance prevents material contamination and ensures the packer’s structural integrity remains intact. It is a crucial factor for maintaining the purity and effectiveness of the injected substance.

Compatibility with Various Resins

Steel packers offer broad compatibility with a wide range of injection resins and chemical formulations. Professionals can confidently use them with epoxies, polyurethanes, acrylics, and cementitious grouts. This versatility makes steel packers a go-to choice for diverse repair and waterproofing projects. Their non-reactive surface ensures the chemical properties of the injection material remain unchanged, guaranteeing optimal curing and performance.

Temperature Stability

Performance in Varying Conditions

Steel packers maintain their performance across a wide range of temperatures. Construction projects often occur in diverse climates, from freezing winters to scorching summers. These temperature extremes do not compromise the structural integrity of steel. The material resists thermal expansion and contraction better than many alternatives. This stability ensures the packer maintains a consistent seal, regardless of ambient conditions. Professionals rely on this consistent performance for critical injection tasks in any environment.

Degradation Prevention

Temperature fluctuations can cause other materials to degrade or become brittle. Plastic packers, for example, may crack in cold weather or soften in extreme heat. Steel, however, prevents such degradation. Its high melting point and low thermal expansion coefficient mean it retains its strength and shape. This characteristic prevents material fatigue and premature failure. Consequently, steel packers offer reliable service without concerns about temperature-induced damage. This reliability ensures project timelines and quality standards remain unaffected by environmental heat or cold.

Longevity and Reusability

Extended Service Life

Steel’s inherent strength and durability contribute to an extended service life for these packers. Unlike plastic or aluminum, steel resists wear and tear from repeated use and harsh conditions. It withstands the abrasive nature of some injection materials and the mechanical stresses of installation and removal. This robust construction means packers last longer, reducing the need for frequent replacements. An extended lifespan translates directly into cost savings for contractors and project managers.

Potential for Multiple Uses

The exceptional durability of steel packers often allows for multiple uses. After an injection job, workers can clean and inspect the packers. If they show no signs of damage or excessive wear, professionals can reuse them for subsequent projects. This reusability significantly enhances cost-efficiency over time. It also reduces waste, aligning with more sustainable construction practices. The ability to reuse packers makes them a valuable, long-term investment for any injection application.

Key Performance Indicators of Steel Injection Packers

Steel injection packers demonstrate superior performance across several critical indicators. These indicators highlight their reliability and effectiveness in demanding applications. Professionals choose them for their consistent results.

Pressure Resistance Capabilities

Withstanding High Injection Forces

Steel packers effectively withstand high injection forces. Their robust construction prevents deformation or failure under extreme pressure. This strength ensures the packer maintains its integrity throughout the injection process. Operators can inject viscous materials at significant pressures without concern. This capability proves crucial for successful and safe operations.

Preventing Leakage and Blow-out

The inherent strength of steel packers prevents leakage and blow-out. A secure seal forms, containing the injected material within the target area. This containment eliminates material escape, even when facing intense back-pressure. Preventing blow-outs enhances safety on the job site. It also ensures efficient material delivery, maximizing project success.

Sealing Efficiency in Diverse Conditions

Effectiveness in Dry Environments

Steel packers achieve high sealing efficiency in dry environments. Their rigid structure allows for precise installation. The sealing element expands uniformly against the bore of the drilled hole. This creates a tight, reliable seal. Operators achieve controlled injection, ensuring the material reaches its intended destination without bypass.

Performance in Wet Environments

Steel packers also perform exceptionally well in wet environments. Water presence does not compromise their sealing integrity. The robust design maintains a secure seal, even when water flows through cracks or voids. This reliability makes them ideal for waterproofing and leak sealing projects. They ensure effective sealant delivery, even in challenging, saturated conditions.

Clean Work and Precision

Full Seal for Controlled Injection

Steel packers provide a full seal for controlled injection. This complete seal directs all injected material precisely where needed. It prevents material from escaping around the packer or flowing back out of the hole. This precision ensures optimal material placement. It also guarantees the repair or stabilization achieves its intended outcome.

Minimizing Material Waste

The superior sealing capability of steel packers minimizes material waste. By preventing leakage and ensuring controlled delivery, they maximize the efficiency of expensive injection materials. Less material is lost, which reduces project costs. This efficiency also contributes to a cleaner work environment. It supports more sustainable construction practices.

Applications Benefiting from Steel Injection Packers

Steel injection packers prove indispensable across various demanding construction and repair applications. Their robust design and superior performance make them the preferred choice for critical projects. They ensure effective material delivery and lasting results in challenging environments.

Concrete Repair and Crack Injection

High-Pressure Resin Injection

Concrete repair often requires injecting specialized resins into cracks. These resins demand high pressure for proper penetration and bonding. Steel packers excel in these scenarios. They withstand the immense forces generated during high-pressure resin injection. This capability ensures the resin reaches deep into the concrete matrix. It effectively fills voids and seals cracks.

Structural Integrity Enhancement

Professionals use steel packers to enhance the structural integrity of concrete elements. Precise injection of repair materials strengthens weakened structures. The packers provide a stable channel for these materials. This controlled delivery ensures the repair material bonds correctly. It restores the load-bearing capacity of the concrete.

Waterproofing and Leak Sealing

Challenging Wet Environments

Waterproofing and leak sealing projects frequently occur in challenging wet environments. Water actively flows through cracks and joints. Steel packers maintain their seal even against significant water pressure. They prevent water from washing away the injected sealant. This reliability is crucial for successful leak remediation.

Effective Sealant Delivery

An effective sealant delivery system is vital for waterproofing. Steel packers ensure the sealant reaches the exact location of the leak. Their rigid construction prevents bypass or premature material escape. This precision guarantees the sealant cures properly. It creates a durable, long-lasting waterproof barrier.

Soil Stabilization and Grouting

Withstanding Abrasive Materials

Soil stabilization and grouting often involve injecting abrasive materials. These materials can quickly wear down less durable packers. Steel packers, however, withstand the abrasive nature of cementitious grouts and other soil-stabilizing agents. Their robust composition ensures consistent performance. They maintain integrity throughout the injection process.

High Injection Force Requirements

Grouting soil requires significant injection force to achieve proper penetration and consolidation. Steel packers meet these high injection force requirements. They handle the pressure needed to compact loose soil or fill large voids. This strength allows for effective ground improvement. It enhances the stability of foundations and excavations. A Steel Injection Packer provides the necessary power for these critical tasks.

Mining and Tunneling

Demanding Underground Conditions

Mining and tunneling operations present some of the most demanding environments for construction tools. These projects often involve unstable ground, high water ingress, and significant geological pressures. Workers use injection packers extensively in these settings for ground consolidation, water control, and structural reinforcement. They inject various materials, such as chemical grouts or cementitious mixtures, into rock formations or soil. This process stabilizes the ground, prevents water infiltration, and enhances overall safety. The success of these critical operations relies heavily on the reliability and performance of the injection equipment. Operators need tools that can withstand the extreme forces and abrasive conditions inherent in underground work.

Robustness for Harsh Environments

Steel packers offer unmatched robustness for harsh underground environments. Their superior strength allows them to endure the high pressures required for effective grouting in rock and soil. These packers resist damage from impacts, vibrations, and the abrasive nature of injected materials. This resilience ensures consistent performance, even when facing challenging geological formations or aggressive chemical agents. The durability of steel also contributes to a longer service life, reducing the need for frequent replacements. This reliability minimizes downtime and enhances operational efficiency in time-sensitive mining and tunneling projects. Professionals trust steel packers to deliver consistent results under the most severe conditions, ensuring the integrity and safety of underground structures. Their ability to perform reliably in such demanding settings makes them an essential component for successful underground construction.

Comparing Steel Injection Packers to Alternatives

Professionals often evaluate different packer materials for specific project needs. Steel injection packers offer distinct advantages over other common types. Understanding these differences helps in selecting the most effective tool for the job.

Steel vs. Plastic Packers

Durability and Pressure Resistance

Steel packers significantly surpass plastic packers in durability. Plastic packers are lightweight and inexpensive. However, they often lack the structural integrity for demanding applications. They can deform or break under high injection pressures. This limitation restricts their use to low-pressure tasks. Steel, a much stronger material, withstands extreme forces. A Steel Injection Packer maintains its shape and integrity even when injecting viscous materials at hundreds of bars of pressure. This superior pressure resistance prevents blow-outs and ensures consistent material delivery.

Cost and Performance Considerations

Plastic packers typically have a lower initial cost. This makes them attractive for single-use or very low-pressure applications. However, their limited durability often leads to higher long-term costs. They require frequent replacement. Their performance can also be inconsistent under varying conditions. Steel packers represent a greater initial investment. Their robust construction and extended lifespan provide superior performance and reliability. They offer better value over the project’s duration. Their ability to handle high pressures and aggressive materials reduces project risks and ensures successful outcomes.

Steel vs. Aluminum Packers

Strength-to-Weight Ratio

Aluminum packers offer a good balance of strength and lightness. They are stronger than plastic and lighter than steel. This makes them suitable for applications where weight is a concern but moderate pressure resistance is still needed. However, steel provides superior absolute strength. For tasks requiring the highest pressure resistance and maximum durability, steel remains the preferred choice. Steel packers can withstand greater mechanical stress and impact without compromising their structural integrity.

Corrosion Resistance and Suitability

Aluminum generally exhibits good corrosion resistance due to its passive oxide layer. This makes it suitable for many environments. However, certain aggressive chemicals or highly alkaline conditions can still corrode aluminum. Steel packers, especially those made from stainless steel alloys, offer excellent corrosion resistance. They withstand a broader range of corrosive injection materials and environmental conditions. This makes them highly suitable for projects involving harsh chemicals or prolonged exposure to moisture. Professionals choose steel for its reliability in chemically aggressive or highly demanding environments where long-term integrity is paramount.

Maximizing the Benefits: Best Practices for Using Steel Injection Packers

Professionals can maximize the advantages of steel injection packers through proper handling and selection. Following best practices ensures optimal performance and extends the lifespan of these critical tools.

Proper Installation Techniques

Correct installation is paramount for effective injection. It directly impacts the success of any repair or sealing project.

Ensuring Optimal Seal

Achieving an optimal seal prevents material leakage and ensures precise delivery. First, thoroughly clean the drilled hole. Remove all debris and dust. This step allows the packer’s sealing element to make full contact with the bore. Next, insert the packer firmly into the hole. Tighten it according to manufacturer specifications. Over-tightening can damage the packer or the substrate. Under-tightening leads to a weak seal. A proper seal directs all injection material into the target area.

Achieving Peak Performance

Peak performance relies on careful installation. Use the correct size packer for the drilled hole. A mismatch compromises the seal and efficiency. Apply steady, even pressure when tightening the packer. This ensures uniform expansion of the sealing element. Before injecting, perform a small test to confirm the seal’s integrity. This proactive step prevents costly material waste and rework. Proper installation guarantees the Steel Injection Packer functions as intended.

Maintenance and Storage

Regular maintenance and correct storage significantly extend the life of injection packers. These practices preserve their functionality for future use.

Extending Packer Lifespan

Clean packers immediately after each use. Remove all residual injection material. Cured material can hinder future sealing capabilities. Inspect packers for any signs of wear, damage, or corrosion. Replace any compromised components. Proper cleaning prevents material buildup. This extends the operational life of the packer.

Preserving Functionality

Store packers in a clean, dry environment. Protect them from extreme temperatures and direct sunlight. These conditions can degrade sealing elements or corrode metal parts. Organize packers by size and type. This makes retrieval efficient and prevents damage from improper handling. Correct storage ensures packers remain in optimal condition. They will be ready for the next demanding application.

Selecting the Right Steel Injection Packer

Choosing the appropriate packer for the job is crucial. It directly influences project success and efficiency.

Matching Specifications to Application

Match the packer’s specifications to the specific application requirements. Consider the hole diameter, injection pressure, and type of material. Packers come in various lengths and diameters. Select one that fits the drilled hole snugly. Ensure the packer’s pressure rating exceeds the anticipated injection pressure. This prevents failure during operation.

Optimizing Project Outcomes

Selecting the right packer optimizes project outcomes. A well-matched packer ensures efficient material delivery. It minimizes waste and reduces the risk of complications. Consult product data sheets and manufacturer recommendations. This helps make an informed decision. Proper selection leads to successful, durable repairs and cost-effective operations.

Steel injection packers are the optimal choice for demanding injection applications. They offer unparalleled durability, sealing integrity, and versatility. Their robust performance delivers more effective, lasting results. This enhances cost-efficiency for a wide range of repair and construction projects. Professionals rely on these packers for superior outcomes.

FAQ

What is the primary function of a steel injection packer?

A steel injection packer creates a temporary, robust seal within a drilled hole. This seal allows for the controlled injection of various materials. It ensures precise delivery of resins or grouts into cracks or voids.

Why do professionals prefer steel injection packers over plastic alternatives?

Professionals prefer steel packers for their superior durability and pressure resistance. Steel withstands high injection forces without deforming. Plastic packers often fail under such demanding conditions.

Can users reuse steel injection packers?

Yes, users can often reuse steel injection packers. Their exceptional durability allows for multiple uses after proper cleaning and inspection. This reusability enhances cost-efficiency for projects.

Which applications benefit most from using steel injection packers?

Applications like high-pressure concrete repair, waterproofing in wet environments, and soil stabilization benefit most. Steel packers excel in demanding conditions requiring robust sealing and high injection forces.

How do steel injection packers perform with aggressive injection chemicals?

Steel injection packers exhibit excellent chemical resistance. They withstand corrosive resins and grouts without degrading. This ensures material purity and maintains the packer’s structural integrity.

Are steel injection packers effective in wet environments?

Yes, steel injection packers perform exceptionally well in wet environments. Their robust design maintains a secure seal even against water pressure. This makes them ideal for leak sealing and waterproofing projects.

What maximum pressure can a steel injection packer typically withstand?

Steel injection packers can typically withstand pressures above 400 bar. This high-pressure capability is significantly greater than other packer materials. It ensures reliable performance in challenging injection tasks.

Post time: Jan-26-2026