M16 Tungsten steel injection pump are high-precision devices. They deliver fluid under high pressure. Tungsten steel components enhance their durability and performance. These pumps are crucial in demanding industrial applications. They require precision, longevity, and resistance to harsh conditions. The industrial injection pump market is significant. Experts project its growth from USD 43.63 billion in 2024 to USD 92.72 billion by 2034. This growth highlights the increasing need for reliable fluid delivery solutions. These pumps offer exceptional volumetric accuracy, often achieving ± < 0.35%. They also provide pulsation-free delivery. This meets stringent international standards for high-precision fluid handling.

Key Takeaways

- M16 Tungsten steel injection pumps are precise machines. They deliver fluids under high pressure. They are important for tough industrial jobs.

- Tungsten steel makes these pumps strong. It helps them last long. It also stops them from wearing out or rusting.

- These pumps work in many places. They help seal cracks in buildings. They also work in car engines and chemical factories.

- M16 pumps are very accurate. They deliver fluids steadily. This helps control industrial processes better.

- These pumps can handle harsh conditions. They resist rough fluids and high heat. This makes them reliable in tough environments.

- Choosing the right pump is important. Consider the fluid type, pressure needed, and where it will be used. This ensures the pump works best.

- Regular checks and cleaning keep the pump working well. Look for wear and tear. Keep seals tight. This helps the pump last longer.

Understanding the M16 Tungsten Steel Injection Pump

Definition and Core Function of M16 Tungsten Steel Injection Pump

What is an M16 Designation?

The “M16″ designation typically refers to a specific model or series within a manufacturer’s product line. It signifies a particular configuration or set of specifications for a tungsten steel injection pump. This designation helps users identify the pump’s capabilities and intended applications. For instance, the M16 model often indicates a robust design suitable for demanding industrial tasks.

Primary Fluid Delivery Role

An M16 Tungsten steel injection pump primarily delivers fluids under high pressure with exceptional precision. Its core function involves moving various liquids from a source to a target area. This process often requires overcoming significant resistance. The pump ensures a consistent and controlled flow, which is critical for many industrial processes.

The Role of Tungsten Steel in Injection Pumps

Hardness and Wear Resistance

Tungsten steel is a superior material for injection pump components due to its remarkable properties. It exhibits high hardness, typically ranging from HRA 89.5 to 93. This extreme hardness provides excellent wear resistance. Components made from tungsten steel withstand constant friction and abrasive fluids without significant degradation. This characteristic ensures the pump maintains its performance over a long operational life.

Corrosion Resistance Benefits

Beyond its hardness, tungsten steel offers significant corrosion resistance. This property makes it ideal for handling aggressive chemicals and corrosive liquids. The material resists chemical attack, preventing damage to critical pump parts. This resistance is crucial in environments where standard metals would quickly corrode, such as in chemical processing or when used as a seawater pump rotor. Tungsten steel’s stable physical properties contribute to its long-term integrity in harsh conditions.

High-Pressure Performance

The inherent strength of tungsten steel allows these pumps to operate effectively under extremely high pressures. An M16 Tungsten steel injection pump can achieve a maximum output pressure of 16000 PSI. This capability is vital for applications requiring deep penetration or forceful fluid delivery. The material’s high compressive strength, ranging from 4700 Mpa, ensures structural integrity even under immense internal forces.

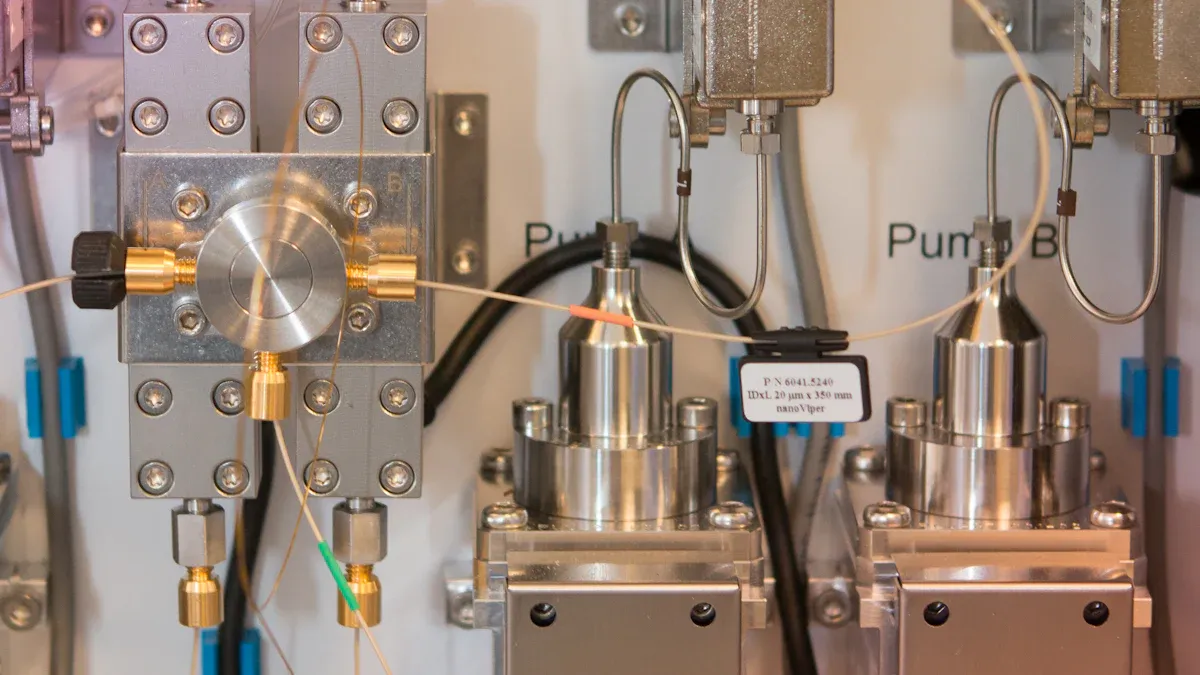

Key Components and Operation of M16 Tungsten Steel Injection Pump

Plunger and Barrel Mechanism

The heart of an M16 Tungsten steel injection pump lies in its plunger and barrel mechanism. This system utilizes an ultra-hard tungsten steel plunger moving within a precisely machined barrel. This design ensures steady pressure buildup and extreme wear resistance. The plunger’s reciprocating motion draws fluid into the barrel and then expels it under high pressure. This robust construction allows compatibility with various materials, including cement slurry, polyurethane, epoxy resin, and polyurea.

Valve Systems

Injection pumps rely on sophisticated valve systems to control fluid direction and prevent backflow. These valves open and close in synchronization with the plunger’s movement. They ensure fluid enters the pump chamber during the intake stroke and exits through the discharge port during the compression stroke. The integrity and precise timing of these valves are essential for efficient operation.

Precision Control

Precision control is a hallmark of these advanced pumps. A premium high-performance motor, featuring a pure copper core, powers the M16 Tungsten steel injection pump. This motor provides enhanced torque and superior power output. It drives the plunger mechanism with consistent force. This precise control results in steady and consistent fluid delivery, which is critical for applications demanding exact metering and blending.

Primary Applications of M16 Tungsten Steel Injection Pump

M16 Tungsten steel injection pumps serve critical roles across numerous industries. Their robust design and precision capabilities make them indispensable for demanding fluid delivery tasks.

Grouting and Construction Applications

Construction projects heavily rely on these pumps for various structural integrity and ground improvement tasks.

Sealing Cracks in Structures

Engineers use M16 tungsten steel injection pumps to seal cracks in concrete and masonry structures. The pump delivers grouting materials, such as epoxy or polyurethane, into fine fissures. Its high pressure ensures the material penetrates deeply, effectively bonding the cracked sections. This process restores structural integrity and prevents further deterioration.

Soil Stabilization Projects

Soil stabilization is another vital application. These pumps inject binders into weak or loose soil, improving its mechanical properties. The high-pressure delivery ensures thorough mixing and distribution of the stabilizing agents.

- The pump enhances the load-bearing capacity of weak or compressible soils.

- It prevents settlement issues in both new and existing structures.

- The process densifies soil, which reduces liquefaction risks during seismic events.

- It strengthens ground bearing capacity for new constructions.

- Furthermore, it stabilizes slopes and fortifies embankments.

- The pump provides crucial foundation support for various projects.

- It manages groundwater flow in structures like dams and retaining walls by creating impermeable barriers.

- It stabilizes soils around tunneling and excavation sites, preventing collapse.

- The pump strengthens unstable slopes, preventing landslides.

- It assists in remediation projects, repairing compromised structures and addressing settlement issues.

- Finally, it stabilizes sinkholes, preventing further collapse and ensuring safety.

Waterproofing Foundations

Waterproofing foundations is essential for building longevity. M16 tungsten steel injection pumps inject waterproofing compounds into foundation walls and slabs. The pump’s ability to deliver material under high pressure ensures complete coverage and penetration. This creates an impermeable barrier, protecting structures from water damage and moisture intrusion.

Automotive Fuel Injection Systems

The automotive industry benefits significantly from the precision and durability of tungsten steel pumps in fuel delivery systems.

Diesel Engine Applications

Diesel engines require extremely high fuel injection pressures for efficient combustion. M16 tungsten steel injection pump components withstand these intense pressures and the abrasive nature of diesel fuel. They deliver precise fuel quantities at the exact moment needed, optimizing engine performance and fuel efficiency.

Gasoline Direct Injection (GDI)

Gasoline Direct Injection (GDI) systems also demand high-pressure fuel delivery directly into the combustion chamber. These pumps provide the necessary pressure and accuracy for GDI engines. This leads to improved fuel economy and reduced emissions. The robust tungsten steel components ensure reliability under continuous high-pressure operation.

High-Pressure Requirements

Modern automotive engines operate under increasingly stringent performance and emission standards. These standards necessitate fuel injection systems capable of delivering fuel at very high pressures, often exceeding 2,000 bar. Tungsten steel pumps meet these demands, offering the durability and precision required for optimal engine function.

Chemical Processing and Dosing with M16 Tungsten Steel Injection Pump

Chemical industries rely on these pumps for safe and accurate handling of various substances.

Corrosive Chemical Handling

Chemical processing often involves highly corrosive liquids. Tungsten steel’s exceptional corrosion resistance makes these pumps ideal for handling such aggressive chemicals. They maintain their integrity and performance, preventing contamination and ensuring operational safety. This capability is crucial for processes involving acids, bases, and other reactive compounds.

Precise Metering and Blending

Many chemical processes require exact ratios of different substances. M16 Tungsten steel injection pump systems offer unmatched precision in metering and blending. They deliver exact volumes of chemicals, ensuring consistent product quality and efficient resource utilization. This accuracy is vital for maintaining process control and achieving desired chemical reactions.

Pharmaceutical Manufacturing

The pharmaceutical industry demands the highest levels of precision and material compatibility. These pumps are suitable for dosing active pharmaceutical ingredients (APIs) and other critical fluids. Their precise control and resistance to contamination ensure product purity and adherence to strict regulatory standards. The durability of tungsten steel also supports long-term, reliable operation in sterile environments.

Oil and Gas Industry Operations

The oil and gas industry presents some of the most challenging environments for equipment. M16 tungsten steel injection pumps thrive in these conditions, providing reliable performance for critical operations.

Well Stimulation and Fracking

Well stimulation and hydraulic fracturing (fracking) demand pumps capable of handling extremely high pressures and abrasive slurries. These pumps inject fluids, often containing proppants like sand, into rock formations to create or enlarge fractures. This process enhances the flow of oil and natural gas. The tungsten steel components resist the erosive effects of these abrasive materials, ensuring consistent pressure and flow rates during these intensive operations. Their robust construction withstands the immense forces involved in fracturing deep underground formations.

Chemical Injection for Inhibition

Operators use M16 tungsten steel injection pumps extensively for chemical injection in oil and gas production. They precisely deliver corrosion inhibitors, scale inhibitors, biocides, and other chemicals into pipelines, wells, and processing facilities. This prevents equipment degradation, maintains flow efficiency, and protects infrastructure from harsh operating conditions. The pumps’ corrosion resistance ensures the integrity of the system when handling aggressive chemicals, safeguarding both assets and environmental compliance.

Offshore and Subsea Use

Offshore and subsea operations require equipment with exceptional durability and reliability due to the remote and harsh marine environment. M16 tungsten steel injection pumps are well-suited for these applications. They perform tasks such as injecting chemicals into subsea pipelines, controlling hydrate formation, and supporting deepwater drilling operations. Their resistance to saltwater corrosion and high-pressure capabilities make them ideal for long-term deployment in challenging underwater conditions, minimizing the need for costly interventions.

Manufacturing and Industrial Processes

Manufacturing and various industrial sectors also leverage the precision and resilience of M16 tungsten steel injection pumps for a wide array of applications.

Lubrication Systems

Many industrial machines rely on precise lubrication to ensure smooth operation and extend component life. These pumps deliver lubricants with high accuracy and consistency to critical moving parts. They maintain optimal lubrication levels, reducing friction and wear in heavy machinery, production lines, and automated systems. The pumps’ ability to handle various viscosities and maintain steady flow contributes significantly to operational efficiency and reduced downtime.

Hydraulic Power Units

Hydraulic power units convert mechanical energy into hydraulic energy, driving a multitude of industrial equipment. M16 tungsten steel injection pumps serve as essential components within these units, generating the high-pressure fluid necessary for hydraulic cylinders and motors. They provide the consistent and powerful fluid flow required for applications such as presses, lifts, clamping systems, and material handling equipment. Their durability ensures reliable performance under continuous high-load conditions.

Specialized Fluid Delivery

M16 tungsten steel injection pumps excel in specialized fluid delivery tasks across various industrial and construction applications. They provide the precision and power necessary for critical operations. For instance, they are crucial for structural repair and crack injection, including the precise installation of cement grouting for anti-theft doors. These pumps also play a vital role in soil stabilization and ground improvement projects, enhancing bearing capacity, preventing settlement, and stabilizing dam foundations and slopes. Furthermore, they are indispensable for waterproofing and leak sealing in basements, tunnels, and water-retaining structures, and for sealing contaminated sites and controlling groundwater. Finally, these pumps address void filling and consolidation in abandoned mines, tunnels, and subsurface cavities, and consolidate weak rock formations in tunneling and mining projects. Their robust design ensures effective delivery of diverse materials for these demanding applications.

Advantages of M16 Tungsten Steel Injection Pump Technology

M16 Tungsten steel injection pump technology offers significant benefits across various industrial applications. These advantages stem from the superior material properties and advanced engineering of these pumps. They deliver reliable performance and contribute to operational efficiency.

Enhanced Durability and Longevity

The robust design of these pumps ensures a long operational life. Their construction withstands demanding industrial conditions.

Reduced Maintenance Needs

Operators experience fewer breakdowns with these pumps. This translates directly into more uptime on critical projects. The pump consistently performs without constant repairs, saving both time and resources.

The robust construction of the pump significantly extends its operational life. Tungsten steel components resist wear and tear from abrasive grouting materials. This inherent durability means the pump requires less frequent maintenance.

Furthermore, several factors contribute to this reduced need for upkeep:

- Superior abrasion resistance protects against abrasive grouting mixtures like sand or cement. This prevents premature wear and tear.

- Significant corrosion resistance guards against chemicals and water-based mixtures. This protects internal mechanisms and extends operational life.

- Reliability in harsh conditions minimizes unexpected interruptions. It ensures stable operation under extreme pressure and with corrosive chemicals.

- A modular design simplifies maintenance procedures and part replacement. This reduces labor costs and downtime.

Extended Service Life

The inherent strength and wear resistance of tungsten steel components lead to an extended service life for the pumps. They endure continuous operation in harsh environments. This reduces the need for frequent replacements and associated capital expenditure. Businesses benefit from a lower total cost of ownership over time.

Unmatched Precision and Accuracy

These pumps deliver fluids with exceptional precision. This accuracy is critical for many industrial processes.

Consistent Fluid Delivery

The advanced engineering of M16 tungsten steel injection pumps ensures consistent fluid delivery. They maintain steady flow rates and pressures. This consistency is vital for processes requiring exact volumes and uniform application. Operators can rely on predictable performance.

Improved Process Control

The precision of these pumps directly enhances process control. Accurate fluid delivery leads to better outcomes in various applications.

- Accurate Material Delivery: The pump’s precision engineering ensures grout is placed exactly where needed. This minimizes waste and prevents over-injection or under-injection. It leads to cost-effective projects and optimal results.

- Consistent Penetration Depths: Its robust design maintains high pressure. This allows grout to reach deep into cracks and voids uniformly. This is crucial for effective structural repair and waterproofing.

- Versatility and Material Compatibility: The pump effectively handles a wide range of viscous and abrasive grouts. This includes thick epoxies and cementitious slurries. It suits diverse project requirements and ensures consistent material distribution.

Resistance to Harsh Environments

M16 tungsten steel injection pumps are built to withstand challenging operating conditions. They perform reliably where other pumps might fail.

Abrasive Fluid Handling

Tungsten steel’s extreme hardness provides excellent resistance to abrasive fluids. The pump handles slurries, grouts, and other abrasive mixtures without significant wear. This capability is essential in construction, mining, and oil and gas industries.

High-Temperature Resilience

These pumps maintain their structural integrity and performance at elevated temperatures. Tungsten steel exhibits high thermal stability. This allows the pumps to operate effectively in high-temperature processes. This resilience ensures consistent operation in demanding thermal environments.

Selecting the Right M16 Tungsten Steel Injection Pump

Selecting the optimal injection pump is crucial for operational success. Businesses must carefully evaluate several factors to ensure the chosen pump meets specific application demands. This section guides users through the selection process, highlighting key considerations for effective pump deployment.

Factors to Consider for M16 Tungsten Steel Injection Pump

Fluid Type and Viscosity

The type of fluid the pump handles significantly influences selection. Engineers consider the fluid’s chemical composition. Corrosive fluids require pumps with enhanced chemical resistance. Abrasive fluids necessitate components with superior wear resistance. Fluid viscosity also plays a critical role. Thicker fluids demand more powerful pumps to maintain desired flow rates. Thin fluids require precise sealing to prevent leakage. Matching the pump’s material and design to the fluid ensures efficient and safe operation, preventing premature wear or system failure.

Pressure and Flow Rate

Application requirements dictate the necessary pressure and flow rate. High-pressure applications, such as well stimulation or structural grouting, demand pumps capable of generating substantial force. The pump’s maximum pressure rating must exceed the system’s operational pressure. Similarly, the required flow rate determines the pump’s capacity. Users select pumps that deliver the necessary volume of fluid within the specified timeframe. Accurate assessment of these parameters prevents underperformance or over-specification, optimizing both efficiency and cost.

Operating Environment

The operating environment presents unique challenges. Extreme temperatures, high humidity, or the presence of hazardous materials affect pump performance and longevity. Pumps operating in corrosive atmospheres require specialized coatings or materials. Outdoor applications need weather-resistant enclosures. Subsea or offshore environments demand pumps designed for saltwater exposure and high external pressures. Environmental considerations ensure the pump’s reliability and safety in its intended setting, protecting both equipment and personnel.

Customization Options for M16 Tungsten Steel Injection Pump

Material Variations

While tungsten steel forms the core of these pumps, manufacturers offer material variations for specific components. For instance, seals and gaskets come in different elastomers or polymers. These materials resist specific chemicals or temperatures. Valve seats and plungers might feature different grades of tungsten steel or ceramic coatings for enhanced performance and extended life. Customizing material choices optimizes the pump for unique fluid characteristics and operational demands, ensuring maximum efficiency and durability.

Connection Types

Integrating the pump into an existing system requires compatible connection types. Manufacturers provide various options for inlet and outlet ports. These include threaded connections, flanged connections, or quick-disconnect couplings. Standard sizes and types ensure seamless integration with existing piping and hoses. Proper connection selection prevents leaks, maintains system integrity, and simplifies installation. Users choose connections based on system pressure, fluid compatibility, and ease of maintenance.

Maintenance and Longevity Tips for M16 Tungsten Steel Injection Pump

Proper maintenance practices significantly extend the operational life and ensure the reliable performance of injection pumps. Regular care prevents costly downtime and maintains efficiency.

Regular Inspection Practices

Consistent inspections help identify potential issues before they escalate. This proactive approach saves time and resources.

Wear and Tear Checks

Operators must regularly check for signs of wear and tear. They inspect components for corrosion and ensure material compatibility, especially in chemical transfer systems. Monitoring pressure and flow performance with gauges and meters helps detect early signs of internal wear, clogged valves, or leakage. Comparing real-time data with designed capacity provides valuable insights. A professional inspection should be scheduled annually. Technicians familiar with the engine type, such as Deutz or Perkins, should perform these checks. They provide detailed reports, including pressure tests and injector data, to assess pump health. Operators should also understand their pump’s components, like plungers and barrels, injectors, and pressure regulators. They can use a magnifying glass to inspect plungers for scoring every 50,000 miles.

Seal Integrity

Maintaining seal integrity is crucial for preventing leaks and ensuring consistent pressure. Operators should inspect hoses, fittings, and seals monthly for fuel stains or dampness. A hissing sound indicates a pressure leak, requiring urgent repair. They tighten loose fittings or replace damaged seals immediately. Keeping an inventory of critical spare parts, including seals, valves, springs, and gaskets, allows for quick replacements and reduces downtime.

Proper Cleaning Procedures

Effective cleaning prevents residue buildup and maintains pump efficiency.

Preventing Clogging

Regularly flushing the pump with clean water or recommended solvents prevents residue buildup. This is especially important after handling chemicals, slurries, or viscous fluids. Replacing fuel filters regularly, every 10,000-15,000 miles or as per the engine’s manual, prevents clogs. Dark or gritty filters signal immediate replacement. Operators should also use high-quality fuel from trusted sources to prevent contamination. They can test for water monthly using fuel testing kits, as water corrodes plungers and injectors.

Chemical Compatibility

When handling various chemicals, operators must ensure cleaning solvents are compatible with pump materials. This prevents damage and maintains the pump’s integrity. Proper cleaning ensures the pump remains ready for diverse applications without cross-contamination.

Troubleshooting Common Issues

Addressing common issues promptly prevents major malfunctions and extends pump life.

Pressure Fluctuations

Pressure fluctuations can indicate several problems. If the pump experiences reduced flow, failing check valves might be the cause. Old chemical residue or damage can prevent proper sealing, so cleaning or replacing them is necessary. Starved suction or cavitation can occur from blocked valves, lines, or an empty supply tank. Operators should check for blockages and ensure adequate supply. An air-locked pump requires priming or bleeding air by opening the discharge to atmosphere until fluid appears. Incorrect RPM or rotation direction, possibly from an inverter setting, also causes fluctuations. Operators check inverter settings and the pump manual. Excessive discharge pressure or partial blockages in the discharge line can also lead to pressure buildup. They check the pressure gauge and safely open lines at various points to test flow rate.

Leakage Detection

Leakage often points to issues with seals or internal components. Operators inspect for external chemical leakage or within the oil reservoir. Improperly sealing check, piston, or diaphragm seals may draw in air. They look for small amounts of leakage around seals. If system pressure exceeds the current sealing capability, they adjust for higher pressure operation by tightening the pressure adjusting screw or loosening set screws and tightening stator screws. If adjusting does not stop the leak, a scratch on the rotor seal might allow high-pressure mobile phase to escape. Replacing the rotor seal and examining the ceramic surface of the stator face assembly for chips or cracks becomes necessary.

M16 Tungsten steel injection pump serves as an indispensable tool across various industries. It supports construction grouting, automotive, and chemical processing. Its superior durability, precision, and resistance to wear and corrosion make it ideal for the most demanding applications. Investing in this technology ensures reliable performance, reduced downtime, and optimized operational efficiency.

FAQ

What does “M16″ signify in these pumps?

The “M16″ designation identifies a specific model or series. It indicates a particular configuration and set of specifications. This helps users understand the pump’s capabilities for industrial tasks.

Why is tungsten steel crucial for these injection pumps?

Tungsten steel offers exceptional hardness and wear resistance. It also provides significant corrosion resistance. This material allows the pumps to operate under high pressure and in harsh environments.

What are the primary applications of M16 tungsten steel injection pumps?

These pumps find use in construction grouting, automotive fuel injection, chemical processing, and the oil and gas industry. They also serve various manufacturing and industrial processes.

How do M16 tungsten steel pumps assist in construction grouting?

They deliver grouting materials under high pressure. This seals cracks, stabilizes soil, and waterproofs foundations. Their precision ensures deep penetration and effective structural repair.

Can M16 tungsten steel injection pumps handle corrosive chemicals?

Yes, tungsten steel possesses excellent corrosion resistance. This makes the pumps ideal for handling aggressive chemicals. They maintain integrity and performance in challenging chemical processing environments.

What are the main advantages of M16 tungsten steel injection pump technology?

Key advantages include enhanced durability and longevity. They offer unmatched precision and accuracy. These pumps also resist harsh operating environments effectively.

How often should one inspect an M16 tungsten steel injection pump?

Operators should perform regular wear and tear checks. They inspect seals monthly. An annual professional inspection is recommended. This proactive approach prevents major issues.

Post time: Dec-02-2025